Overall Objectives

1. Stabilize and expand profits through dual management approach

Commodities

Strengthen business foundation with a view to increasing production capacity, and work to improve competitiveness and profitability

Specialties

Expand scale by strengthening and differentiating growth fields to cultivate new businesses, and work to stabilize and expand revenue base

2. Strengthen safety, and cultivate culture of safety

Prioritize safe plant operation

3. Maintain solid financial base

Maintain solid financial base to facilitate timely large investments and M&A

4. Promote energy conservation and CO2 use

Continue investment in energy conservation

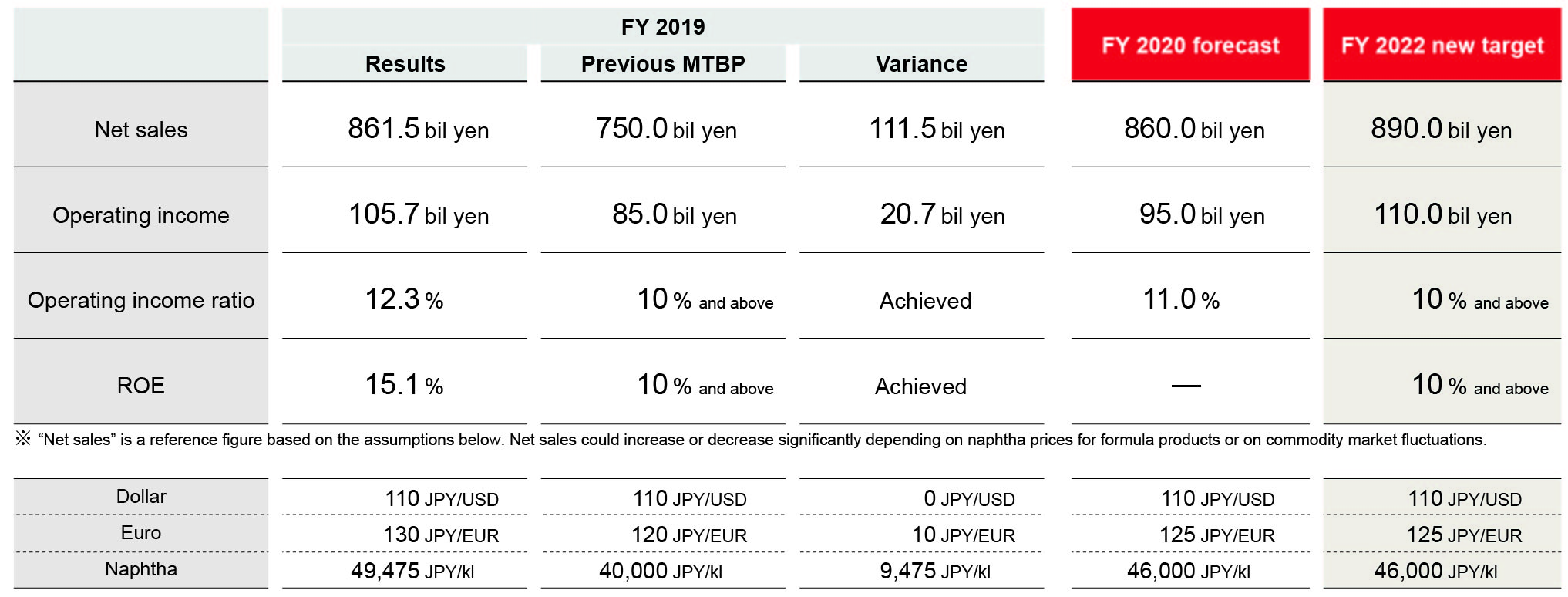

Targets

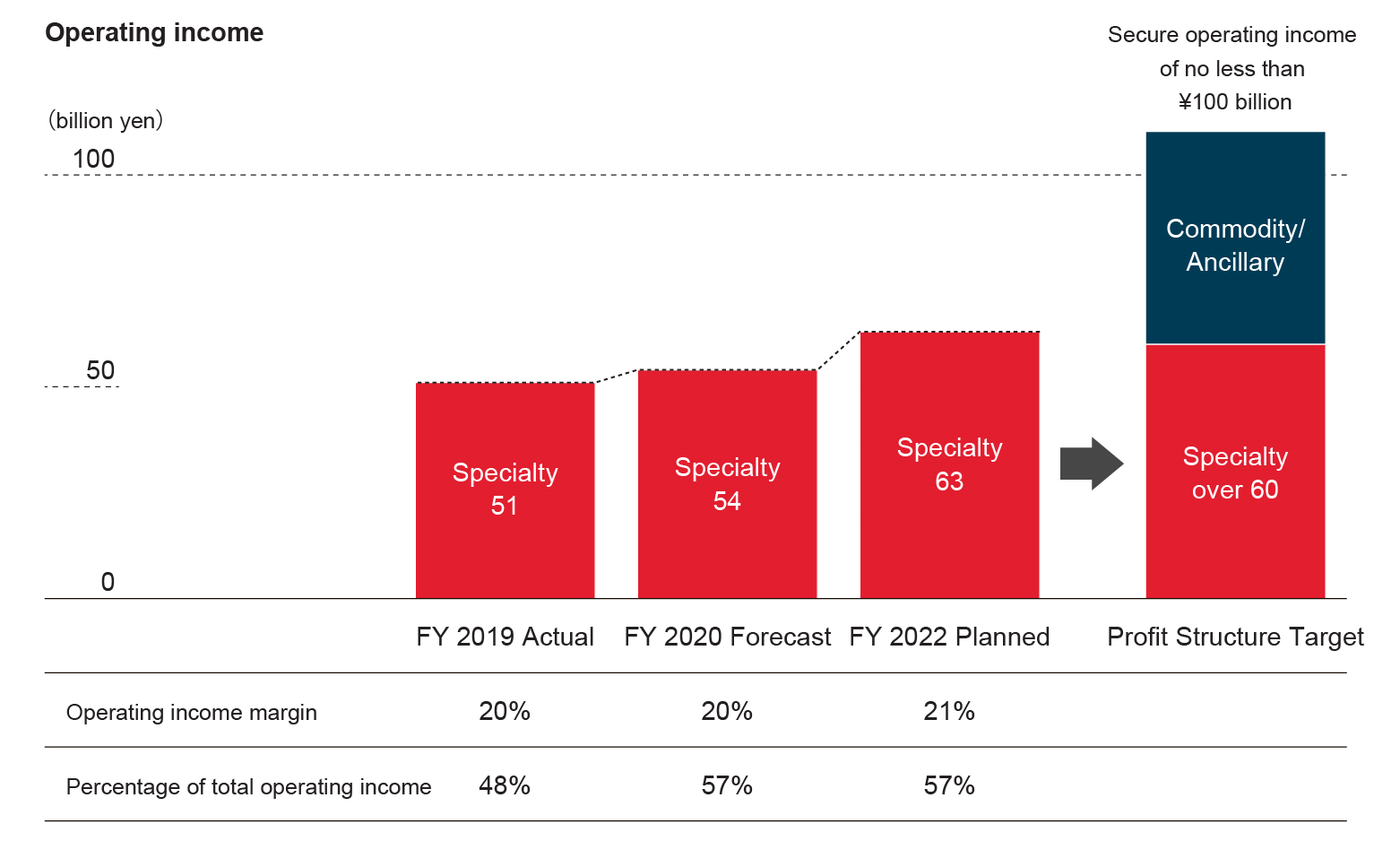

Desired Profit Structure

We plan to generate earnings in excess of ¥60 billion in our specialty products, whose earnings are downwardly rigid, and to secure total earnings of no less than ¥100 billion even when commodity earnings are weak.

Note: Specialty profits

Specialty profits includes profit from our functional products segment, from the functional polymer products of the Petrochemical Division, and from the functional polyurethane products of the Chlor-alkali Division.