Reduce GHG Emissions in the Tosoh Group

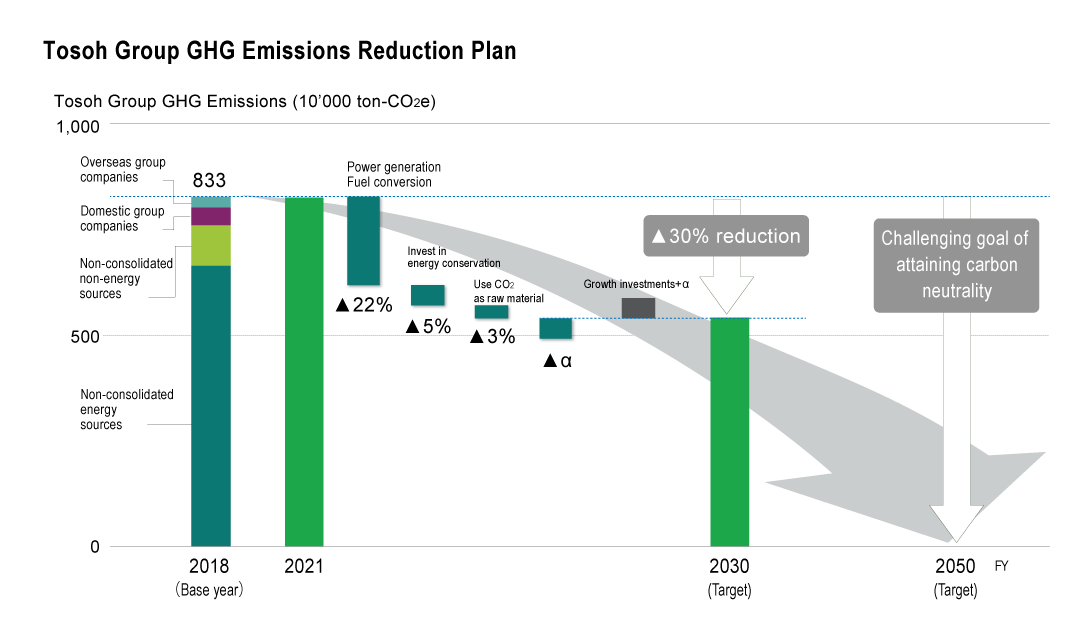

The reduction of GHG emissions, a major cause of climate change, is a social issue of high concern around the world. In 2022, we formulated a new policy to reduce GHG emissions in the Tosoh Group in line with a declaration by the Japanese government to aim to achieve a carbon-neutral society by 2050 and a review of our fiscal 2031 reduction targets.

The Tosoh Group recognizes the reduction of GHG emissions through our business activities as a priority issue to ensure the Group’s medium- to long-term growth and is thus reducing GHG emissions through energy conservation and fuel conversion as well as looking into technologies for the effective use of CO2.

Tosoh will promptly implement various measures toward decarbonization, taking into account trends in Japan's energy policy, technological innovation, and the distribution of CO2-free fuels.

Measures to Reduce GHG Emissions

1. Pursue energy conservation

Tosoh utilizes internal carbon pricing to assess the cost of different levels of GHG emissions as a reference point for investment decisions and will raise the unit pricing to ¥6,000/t-CO2 to accelerate energy conservation efforts.

2. Decarbonize the energy we use

Our major GHG emissions reduction target is to decrease CO2 emitted from our in-house thermal power generation facilities. We will progressively phase out coal and other fossil fuels that produce large quantities of GHGs, replacing them with biomass, liquefied natural gas, and CO2-free hydrogen and ammonia. We will also step up our efforts to introduce renewable energies, such as solar power, to decarbonize energy used by the Tosoh Group.

3. Capture and utilize CO2

Tosoh has teamed up with external research institutions and the Japanese government to develop technologies that separate and capture CO2 emitted by power generation facilities and production processes. These technologies will also make possible the use of the recovered CO2 as a raw material in manufacturing polyurethane and other products.

4. Invest in GHG emissions reduction

To fund these measures, Tosoh will invest around ¥120 billion by fiscal 2031 in addition to standard capital investment. We will invest about ¥60 billion of that sum immediately over the three years from fiscal 2023 through fiscal 2025.

Promotion System

The Tosoh Group’s climate change initiatives are being promoted primarily by the CO2 Reduction and Effective Use Promotion Committee and the Central Energy Management Committee. We are also collecting information on social trends, regulatory requirements and risk management related to climate change, and sharing this information with Tosoh Group companies. Matters related to these activities are reported to the respective board of directors for approval as appropriate, and instructions are received as necessary.

Promotion System for Reducing GHG Emissions

- Board of Directors

- CO2 Reduction and Effective Use Promotion Committee (est. May 2018)

- CO2 Reduction and Effective Use Strategy Team*

- Task Force Nanyo*

- Task Force Yokkaichi*

* Est. June 2021

1. CO2 Reduction and Effective Use Promotion Committee

The committee is chaired by the overseeing Tosoh director, who is responsible for identifying issues, formulating policies, and conducting investigations and analyses with regard to using alternative fuels for in-house thermal power generation facilities, the reduction of GHG emissions, including the introduction of renewable energies, and the effective utilization of CO2 through recovery and conversion to raw material. In June 2021, the CO2 Reduction and Effective Use Strategy team and the CO2 Reduction and Effective Use Task Forces at the Nanyo and Yokkaichi Complexes were established to strengthen the system for promoting CO2 reduction and effective use.

2. Central Energy Management Committee

The committee, chaired by the head of CO2 Reduction and Effective Use Strategy, works to reduce overall energy consumption. This includes improvements in energy consumption in production and transportation, and the promotion of alternative energy sources. Specifically, the committee discusses and determines energy management policies, medium-term, long-term and annual plans, compliance status and evaluation methods, and matters related to energy management.

Message from the Head of CO2 Reduction and Effective Use Strategy

The CO2 Reduction and Effective Use Promotion Committee, established in 2018, has been investigating the use of alternative fuels in power generating facilities and the effective utilization of CO2 as a raw material for chemical products in addition to conventional efforts to reduce CO2 through energy conservation. Going forward, we will set specific measures to achieve our newly formulated reduction targets for fiscal 2031 and accelerate efforts to drive the innovation necessary to achieve carbon neutrality by 2050. We will continue striving to increase the corporate value of the Tosoh Group through our GHG reduction initiatives.

Sosuke Matsushima

Vice President

Head of CO2 Reduction and Effective Use Strategy

CO2 Reduction Efforts

Biomass Power Generation

Tosoh has decided to build a new biomass-fired power plant and close an aging coal-fired power plant at its Nanyo Complex. The new biomass power plant can use a wide variety of fuels, including waste fuels such as wood fuels, construction waste materials and RPF*, in place of coal. In the future, Tosoh plans to burn biomass exclusively, thereby reducing CO2 emissions by approximately 500,000 tons per year. The new biomass power plant is scheduled to start generating electricity in April 2026. Tosoh is also looking at ways to improve the biomass co-combustion rate at existing power generation facilities and will continue efforts toward decarbonization by shifting to alternative fuels.

*RPF (refuse-derived paper and plastic densified fuel): A high-quality solid fuel containing primarily paper and plastics that are difficult to recycle from industrial waste

Biomass Power Generation and Carbon Neutrality

A wide range of biological organic substances such as wood, agricultural and marine products, and food sources are used as raw materials for biomass power generation. Fossil fuel consumption ballooned with the onset of the industrial revolution but today with global calls to reduce CO2, biomass has once again come into the spotlight as a viable energy source and an effective method of power generation that can be regarded as carbon neutral.

Tosoh is looking into the stable procurement of diverse biomass sources such as wood biomass pellets, torrefied biomass pellets and RPF, and will promote efforts to reduce GHG emissions using alternative fuels for in-house thermal power generation.

Installing Additional Gas Turbines

Tosoh’s Yokkaichi Complex serves as a base for our petrochemical business with its ethylene plant and an in-house thermal power plant that uses petroleum coke as fuel. In promoting energy conservation and the effective use of CO2, one of the basic policies of our previous medium-term business plan, Tosoh introduced an advanced control system for the ethylene plant and improved the efficiency of the gas turbines and naphtha cracker furnace. We are also considering the installation of additional gas turbines as well as the use of petroleum coke and biomass co-firing as further measures to reduce CO2.

Going forward, we will continue to focus on conserving energy by upgrading equipment at energy-intensive plants and reducing energy-derived CO2 emissions.

Gas turbine

Basic Study on Establishment of Ammonia Supply Center at Shunan Industrial Complex

A project jointly proposed by Tosoh and three other companies in the Shunan Industrial Complex was adopted for a subsidy program regarding “Measures to Promote the Introduction of Non-Fossil Energy (Support Project for Establishment of Hydrogen and Fuel Ammonia Supply Center at Industrial Complex)” by the Agency for Natural Resources and Energy under the Ministry of Economy, Trade and Industry.

The project aims to establish at the Shunan Industrial Complex a carbon-free ammonia supply system with an annual capacity of over one million tons by 2030. Ammonia co-firing demonstration tests will be conducted using actual equipment. In cooperation with Shunan City and the Chemical Engineering Society, the project will work to achieve a carbon-neutral complex.

Initiatives for the Effective Use of CO2

CO2 Separation and Recovery (Amine Used to Recover CO2)

As moves toward decarbonization accelerate, demand is expected to increase for CO2 recovery methods. While the chemical absorption method is particularly suited for recovering CO2 from fossil fuel boilers, one of the challenges has been to ensure resistance to nitrogen oxide (NOx) in exhaust gas.

Tosoh has developed an amine with excellent resistance to NOx. This high-performance amine can be used to recover CO2 from the exhaust gas generated when fossil fuels are combusted. Being both highly energy-efficient and NOx-tolerant, the amine raises expectations for application in the stable, long-term recovery of CO2 from a wide range of exhaust gases.

Tosoh is continuing to optimize its amine as well as the CO2 recovery system at its demonstration test plant.

CO2 recovery demonstration test plant

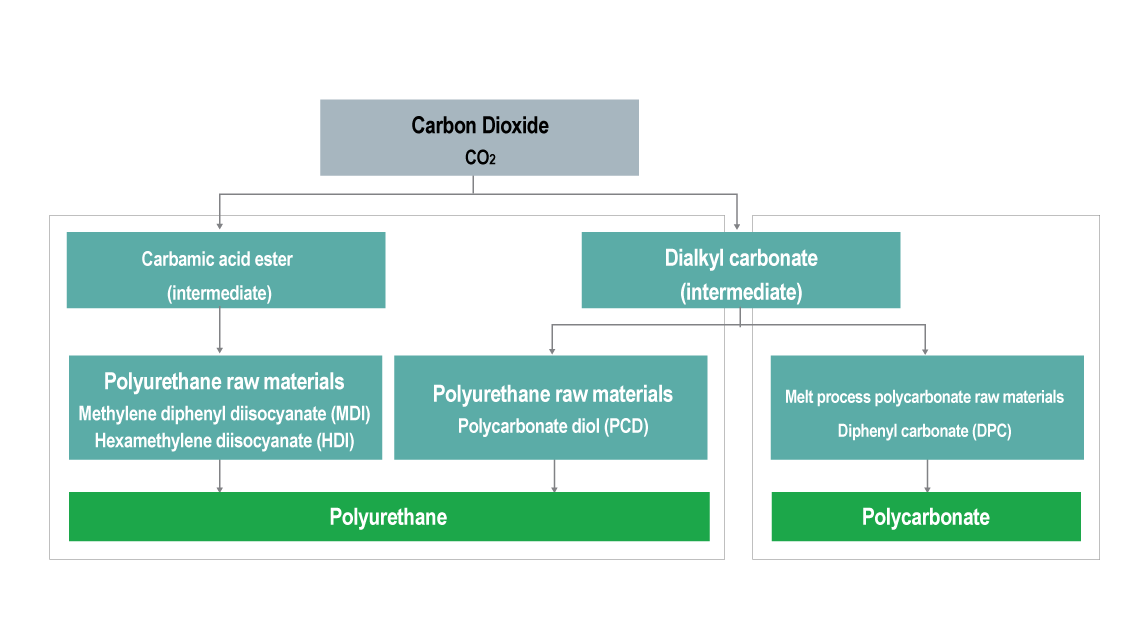

Using CO2 as Raw Material in Production of Functional Chemicals

Tosoh supervised the parties involved in a joint proposal adopted as a project financed by the Green Innovation Fund run by Japan’s New Energy and Industrial Technology Development Organization (NEDO). Proposal collaborators include another company, universities and national research institutes.

The parties aim to reduce CO2 emissions during the manufacture of polycarbonate and polyurethane and strive to develop technology for converting CO2 into a raw material for functional plastic production by 2030. Their hope is to achieve the same plastic manufacturing cost as current products through pilot-scale demonstration production while improving the functionality of the plastic produced.

We believe that our efforts to reduce GHG emissions will lead to medium- to long-term business growth. As such, we continue to contribute to the realization of a sustainable society, promoting the development of technologies to raise the efficiency of CO2 use.

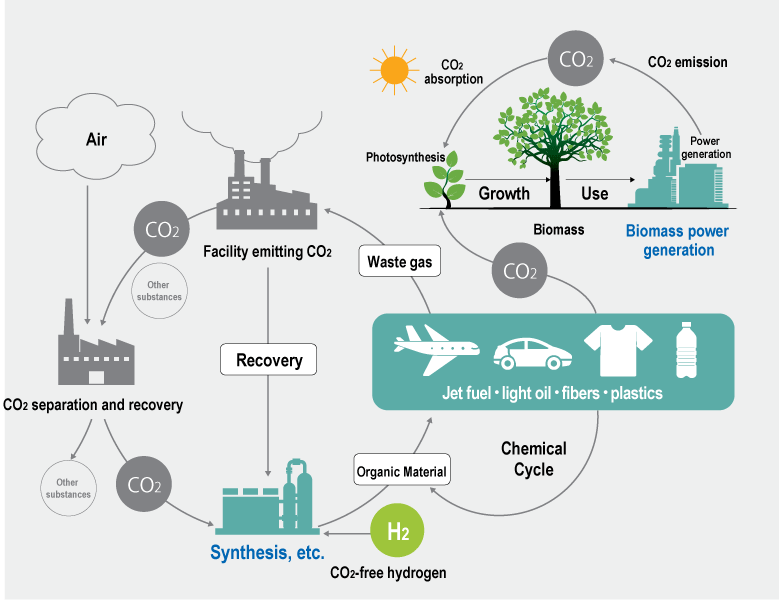

Carbon Recycling

Technologies for the separation, recovery and effective use of CO2, including turning it into a raw material for chemical products, are expected to be key to reducing GHG emissions and becoming carbon-negative as we head toward the target of realizing a carbon-neutral society by 2050. In addition to a chemical absorption method using an amine to recover CO2, Tosoh is working on the development of an energy-saving CO2 separation and capture process using CO2 separation membrane modules. We are also promoting technologies for the effective utilization of CO2, including the direct capture of CO2 from combustion exhaust gas (DAC*), and will continue to develop technologies for carbon recycling.

*Direct Air Capture (DAC) is a technology for capturing extremely low concentration CO2 directly from the atmosphere.