Climate change is one of the world's most pressing societal issues. The Tosoh Group recognizes that contributing to the reduction of greenhouse gas (GHG) emissions through its business activities is the most important theme for its medium- to long-term growth and is promoting the reduction of CO₂ emissions through energy conservation and fuel conversion, as well as the study of technologies for the effective use of CO₂.

In October 2020, the Japanese government declared its intent to achieve a decarbonized society by 2050. In response, Tosoh in 2022 has established a new GHG emissions reduction policy for the entire Group.

Tosoh also expressed its endorsement for the Task Force on Climate-Related Financial Disclosures Task Force (TCFD*) recommendations in November 2019. In line with the recommendations, the Group will continue to disclose information on its initiatives.

*The organization was established by the Financial Stability Board to formulate a disclosure framework that is helpful in understanding climate-related risks and opportunities for companies. In June 2017, the company published recommendations related to items of information disclosure.

Tosoh's response to climate change issues is promoted mainly by the CO₂ Reduction and Effective Use Promotion Committee and the Central Energy Management Committee. We are also gathering information on social trends, regulatory requirements, and climate change-related risk management, and sharing this information with companies in the Tosoh Group. Matters related to these activities are reported to the respective Board of Directors for approval as appropriate, and instructions are received as necessary.

The committee is chaired by the director in charge (president and representative director after March 2022). The committee promotes the identification of issues, formulation of policies, research and analysis, and progress management for emission reductions. This includes shifting to alternative fuels and effective utilization of CO2 through recovery and conversion to raw materials. These efforts actively promote the reduction and effective utilization of energy-derived CO2 emitted from the operation of in-house thermal power generation facilities.

The committee, chaired by the head of the CO₂ Reduction and Effective Use Strategy team, is working to achieve comprehensive energy savings. This includes improvements in energy consumption in production and transportation, and the promotion of alternative energy sources. Specifically, the committee discusses and determines policies for energy management, medium-term and annual plans, compliance status and evaluation methods, and energy management-related matters.

The Tosoh CSR Advancement team serves as the secretariat, sharing information on climate-related social trends and exchanges opinions with the aforementioned committees on the compilation of Group-wide GHG emissions.

Tosoh participates in the Low Carbon Society Action Plan of the Japan Chemical Industry Association (JCIA). In March 2019, the JCIA reviewed the CO₂ emissions reduction targets for the Japanese chemical industry. Capitalizing on this opportunity, Tosoh has set a target of 6% reduction in energy-derived CO₂ emissions in FY2026 from BAU* emissions (FY2014 baseline).

Meanwhile, as GHG emissions reduction is a global-scale social issue of the greatest concern, Tosoh has formulated a new GHG emissions reduction policy for the entire Group in response to the Japanese government's declaration of carbon neutrality by 2050 and its revised GHG emissions reduction target for fiscal 2031.

Moreover, Tosoh utilizes an internal carbon pricing system to promote capital investment that contributes to energy conservation.

Note: Figures with a ✔ have been certified by an independent third-party institution.

Tosoh's GHG emissions in fiscal 2022 totaled 7,567 kilotons-CO₂e, up 170 kilotons-CO₂e from fiscal 2021. This is attributed to the impact of increased production as the world recovers from the market decline caused by the pandemic. On the other hand, with regard to the goal of reducing energy-derived CO₂ emissions, we are aggressively moving forward with capital investment in fuel conversion and energy conservation. GHG emissions for the entire Tosoh Group rose 2.7% compared with fiscal 2021.

To ascertain greenhouse gas emissions across the entire Tosoh Group supply chain, we calculate emissions by scope.

*Values for FY 2019-2021 have been retroactively adjusted to match the FY 2022 data calculation method. The scope of aggregation was expanded from 26 domestic and overseas group companies to 52 companies, and the target of calculation was expanded to include manufacturing and logistics bases, and calculated according to the method for calculating adjusted GHG emissions. Moreover, GHG emissions from waste fuels are not included here and are listed separately.

Tosoh is promoting the use of energy from internally and externally generated waste. We are striving to reduce consumption of fossil fuels by effectively utilizing waste oil, waste liquids, general waste plastics, and industrial waste generated from manufacturing processes as fuel. The standard used to collect activity data and calculate emissions is the Act Concerning the Promotion of the Measures to Cope with Global Warming (Japan, revised 2005).

Moreover, the emission coefficient is calculated using an adjusted emission coefficient to accommodate the use of renewable energy electricity. The adjusted GHG emissions calculation does not include emissions from waste used as energy.

| |

FY 2019 |

FY 2020 |

FY 2021 |

FY 2022 |

| Waste fuel-derived GHG emissions |

54 |

49 |

50 |

55 |

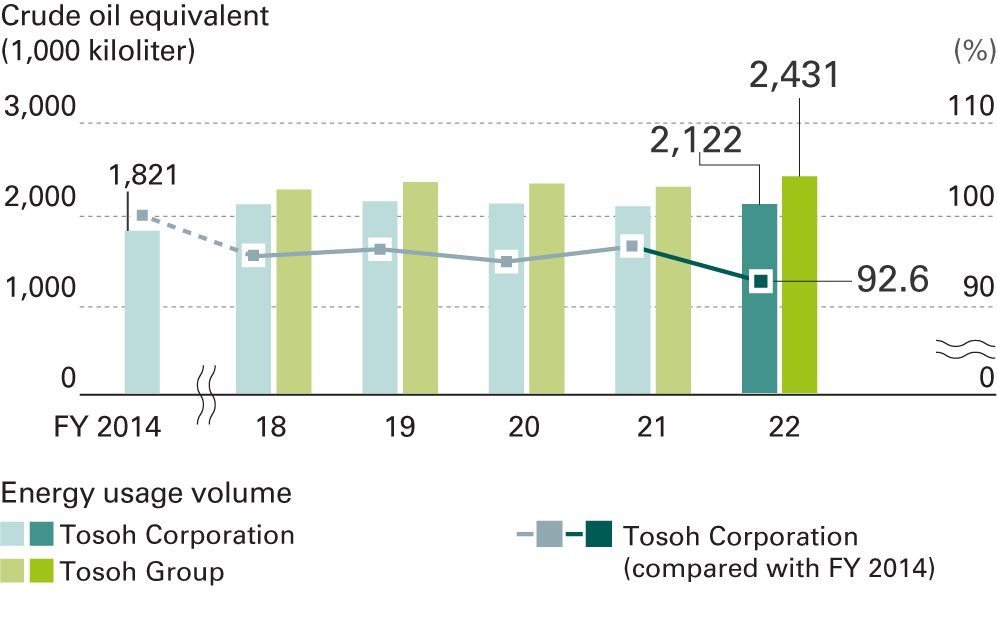

Energy Consumption Index of Energy Used (Tosoh Group)

Tosoh's energy intensity index for fiscal 2022 was 92.6% compared with fiscal 2014. Energy efficiency improved by 4.0 percentage points compared with fiscal 2021 due to increased production volume and other factors.

Energy consumption (crude oil equivalent of 1,000 kl) is calculated based on the Japan’s Act on the Rational Use of Energy (Energy Conservation Act), and the energy consumption from biomass is added. The energy intensity index (compared to FY2014) is calculated based on the Energy Conservation Act. When calculating energy consumption specifically for Tosoh Corporation, we deduct the energy sold to other firms. Data for fiscal 2018 does not include emissions from the former Tosoh F-Tech, Inc.

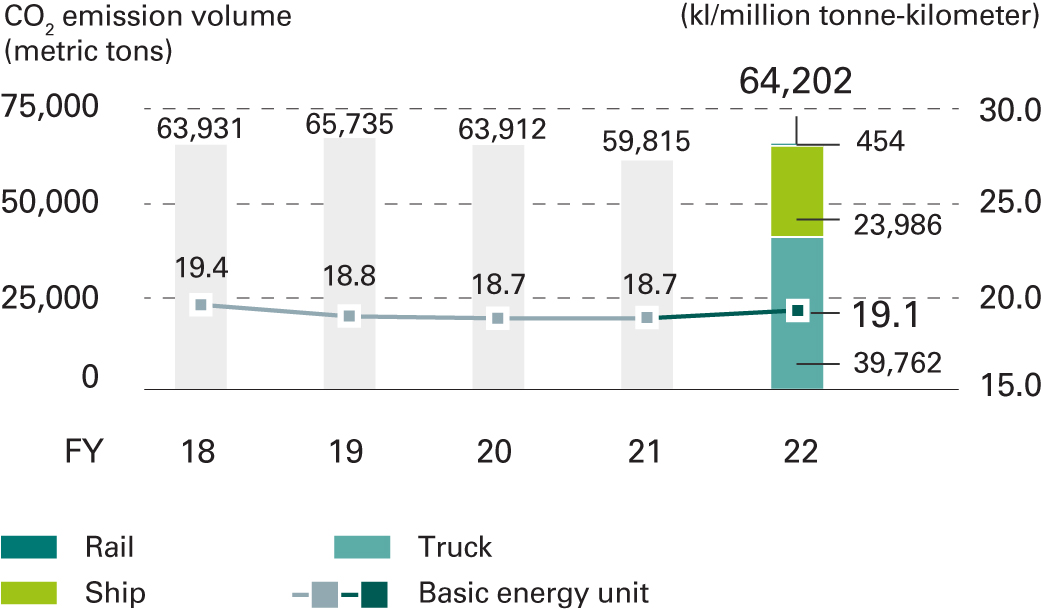

Logistics-Related CO2 Emissions and Basic Energy Unit

In fiscal 2022, Tosoh’s logistics CO₂ emissions increased by 7.3% compared with fiscal 2021, mainly due to increased energy consumption resulting from higher transportation volume. The logistics basic energy unit was 19.1, a regression from fiscal 2021. Factors contributing to the regression include a decrease in the ship ratio (increase in the truck transport ratio) and a decrease in the volume transported per voyage (load factor) in marine transport.

To reduce CO₂ emissions, we are continuously promoting energy efficiency through a modal shift in transport that sees us promoting marine and rail transport and improving transportation fuel efficiency. Tosoh Logistics Corporation, a Group company, completed renovation of its ethylene carrier, the Shoyo, in December 2020. The ship has been designed to be environmentally friendly, with an optimized hull, the Eco-Stator—a rectifying plate that improves propeller efficiency—and friction resistance-reducing paints to improve propulsion performance. The vessel also features an electronic charting system with Track Control, an automatic course maintenance system to achieve optimal navigation and fuel consumption.

*Logistics basic energy unit—energy consumption converted to crude oil (kiloliter) / transport tonne-kilometers (one million tonne-kilometers)

Assessing Risk and Opportunity

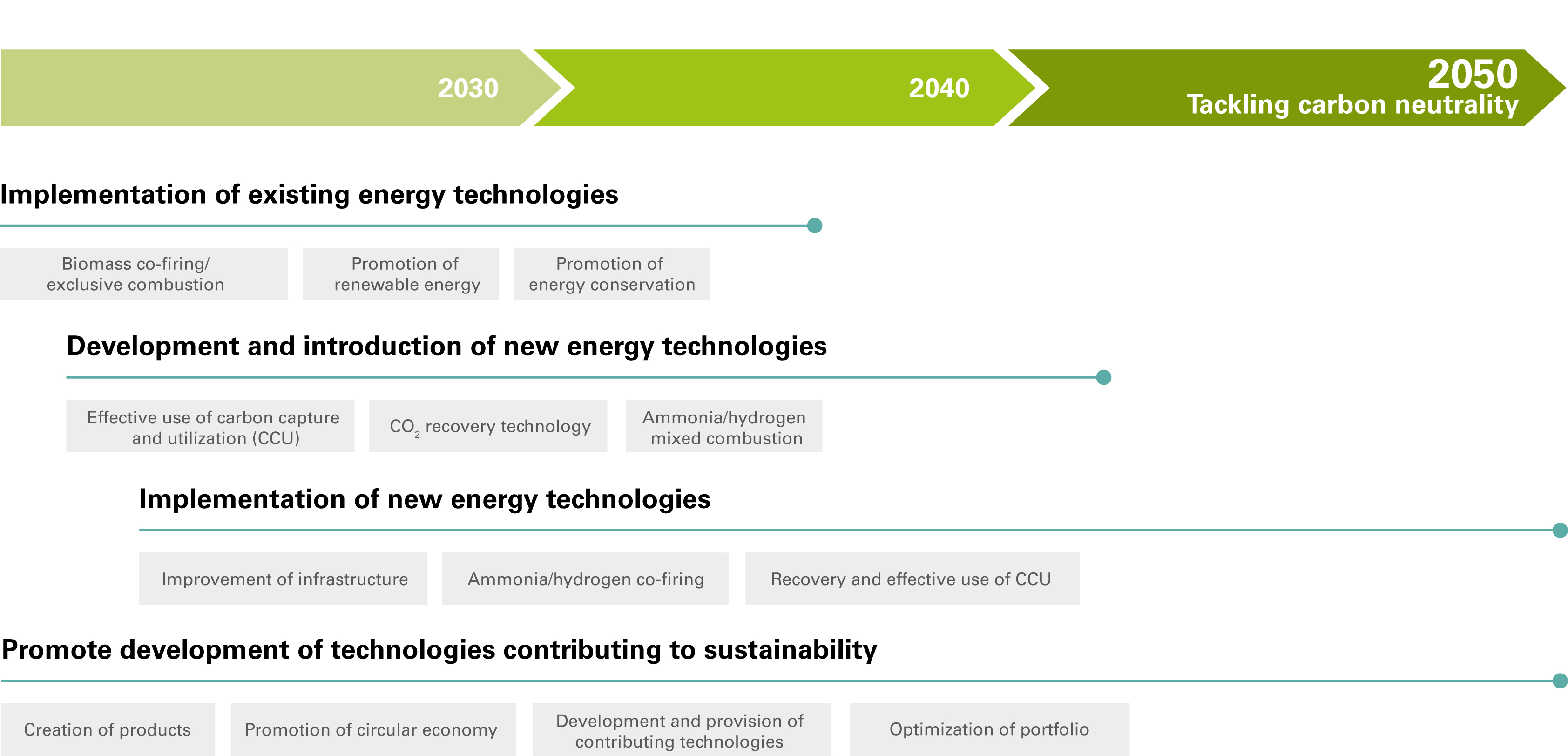

The CO₂ Reduction and Effective Use Promotion Committee promotes strategy planning, issue organization, policy formulation, research and analysis, and progress management related to CO₂ emissions reduction and effective utilization as a chemical raw material. Through an assessment of risks and opportunities, we are formulating a roadmap to support our contribution to the challenge of achieving carbon neutrality by 2050.

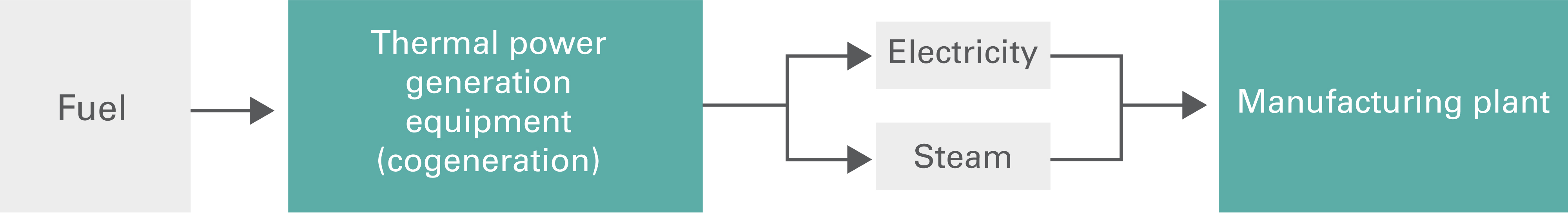

Tosoh operates a high-efficiency cogeneration* in-house power plant to ensure inexpensive and stable power needed for the production of chemical products, and this poses a risk for the company. The introduction of carbon taxes and emissions trading schemes in the future will create new cost burdens. If a carbon price of 100$/t-CO₂ were applied, for instance, and emission credits equivalent to 100,000 t-CO₂ were purchased, the cost would be approximately 1 billion yen.

As a means of capturing opportunities, we have begun to consider evaluating the environmental contribution of existing products and will expand sales in response to the growing market for products and services that reduce environmental impact. In R&D, the Group has designated Life Science, Electronic Materials, and Environment and Energy as priority fields, and is working to create products and services that respond to market needs and climate change-related social issues.

*Cogeneration: A system that recovers and utilizes heat produced during power generation.

Assumed Climate-Related Risks and Opportunities

|

Risk |

Opportunity |

| |

Medium term (~2030) |

Long term (~2050) |

Medium term (~2030) |

Long term (~2050) |

| Policies and regulations |

Increased costs due to carbon pricing (carbon tax, emissions trading) |

Innovations for a low-carbon, decarbonized society

● Products and services that reduce environmental impact (expand sales of environmentally friendly products)

● Complexes using clean energy

● CO₂ separation, recovery, and recycling technologies

Strengthening of infrastructure

● Urban infrastructure construction (building materials)

● Construction of information network (IT materials)

● Support for a better life (improvement of QOL)

● Construction of complex infrastructure (safety and stable supply) |

|

|

|

|

|

|

| Technology |

Introduction of co-firing technology (hydrogen, ammonia, biomass, waste plastic) |

Introduction of renewable energy |

|

|

| Market and reputation |

Raw materials and energy supply and prices |

| Consumption orientation and stakeholders |

| Climate |

Abnormal weather (wind disasters, heavy rain, drought) |

Chronic damage (rising temperatures, rising sea levels) |

|

Roadmap for 2050

Reduction of CO₂ in Each Division

Capital Investment Toward Energy Conservation

One of the basic policies of Tosoh's new medium-term business plan is to mobilize its efforts to reduce and effectively utilize CO₂ emissions. Energy conservation is a social responsibility, and the company will continue to make constant investments in this area.

To this point, Tosoh has made energy-saving modifications to caustic soda electrolyzers at the Nanyo and Yokkaichi Complexes, introduced an advanced control system for the Yokkaichi ethylene plant, installed gas turbines and high-efficiency naphtha cracking furnaces at Yokkaichi Complex, introduced state-of-the-art turbines and rotors for the in-house power generation facilities at Nanyo, and introduced optimal load balancing system for the power plant at Nanyo Complex. From fiscal 2021, we have made a series of capital investments toward reducing coal consumption by increasing the ratio of biomass fuel co-firing. We will continue to promote energy conservation by retrofitting energy-intensive plants and accelerate the reduction of energy-derived CO₂ emissions.

Gas turbines (Yokkaichi Complex)

Active Use of Biofuels in Manufacturing Activities

In fiscal 2022, Tosoh used approximately 25,000 tons of biofuel, resulting in a reduction of approximately 33,000 tons of CO₂ emissions.1 In January 2021, Tosoh signed an agreement with Shunan City in Yamaguchi Prefecture and Izumi Sangyo Co., Ltd. for the use of wood pruned from trees at public facilities in Shunan City as biomass to fuel the Nanyo Complex in-house power generating plant. Izumi Sangyo processes pruned trees at facilities in Shunan City into chips at its Shunan Biomass Center, and Tosoh co-fires the chips, a woody biomass fuel, with coal at the Nanyo Complex power plant, thereby reducing GHG emissions. Some of our overseas group companies utilize biofuels, resulting in a reduction of approximately 39,000 tons of CO₂ emissions in fiscal 2022.2

1 Calculated from the calorific value of wood and common coal and the emission factor of common coal as specified in Japan’s Act Concerning the Promotion of the Measures to Cope with Global Warming.

2 Calculated from the calorific value of wood and crude oil and the emission factor of common coal as specified in the Act Concerning the Promotion of the Measures to Cope with Global Warming.

Effective Utilization of Waste in Cement Plants

The cement plant at Tosoh's Nanyo Complex effectively utilizes internal and external waste materials as raw materials for cement and heat energy sources. Of this amount, Tosoh accepted and processed a total of 22,000 tons of plastic waste, automobile shredder residue, and shredder residue from waste home appliances, as heat energy sources. This resulted in a reduction in CO₂ emissions from fossil fuels by approximately 55,000 tons in fiscal 2022.

Cement plant (Nanyo Complex)

Licensing of Energy-Saving Technologies to Reduce CO2

Tosoh has developed energy-saving technologies for caustic soda and vinyl chloride monomer (VCM) manufacturing processes, and grants licenses to its cultivated technologies overseas. The use of such technologies contributes to the reduction of CO₂ emissions from local manufacturing plants.

New Type of Caustic Soda Electrolyzer

Caustic soda is produced by electrolyzing raw materials using the ion exchange membrane (IM) process. As Japan's largest manufacturer of IM brine electrolysis, Tosoh jointly developed an energy-saving electrolyzer in 1995, and since then has continued to improve the technology. Tosoh licenses the technology it has developed in this way to companies in Japan and overseas, supporting them in their efforts to save energy.

The company has granted licenses to 33 countries representing caustic soda production of approximately 20 million tons, leading to reductions in CO₂ emissions through the provision of technology. In FY2022, the estimated CO₂ emission reduction effect from licensing (for caustic soda, this is limited to the portion of production method conversion from the mercury and diaphragm methods) amounted to approximately 610,000 tons-CO₂ at a caustic soda production volume of around two million tons.*

*This estimate is based on the amount of energy saved by converting from the mercury and diaphragm methods to Tosoh's IM brine electrolysis technology for the licensee's estimated production volume. The country-specific CO₂ emission coefficients for electric power are the values published in the 2021 edition of the IEA’s CO₂ Emissions Factors.

New type of caustic soda electrolyzer

Heat Recovery Equipment for VCM

VCM, the raw material for vinyl chloride resin, is produced by the thermal decomposition of ethylene dichloride (EDC). A large amount of heat is released in the cracking furnace that performs this pyrolysis. Tosoh recovers this heat and uses it as part of the source for heating the cracking furnace, leading to a reduction in fuel usage. This technology has been licensed to companies in three countries overseas, generating a CO₂ reduction effect of about 36,000 tons.*

*This estimate is based on energy recovery prior to and following the introduction of the technology, compared with the production capacity at the time the license was issued.

Technical Study on Recovery and Effective Utilization of CO₂ Emitted from Power Plants

Tosoh is studying technologies for the effective utilization of CO₂. Specifically, we are investigating technologies for the separation and recovery of CO₂ emitted from power plants and the conversion of recovered CO₂ into raw materials for polyurethane. As an example, a theme related to CO₂ conversion to raw materials and separation and recovery technology has been selected by Japan’s New Energy and Industrial Technology Development Organization (NEDO) as part of its Feasibility Study Program. Tosoh endorses the Challenge Zero declaration by the Japan Business Federation (Keidanren) and publicly announces the details of its initiatives. *

*Challenge Zero is a new Keidanren initiative to promote innovation toward the realization of a decarbonized society, the prime objective of the Paris Agreement.

Coal-Fired In-House Power Plant at Nanyo Complex

The production of chemicals requires not only electricity, but large amounts of steam. Tosoh makes effective use of steam produced during power generation at its in-house power plant. Despite being a subcritical pressure power generation facility, the power plant’s efficiency—including steam—is higher than that of ultra-supercritical pressure power generation facilities.* In this way, Tosoh's cogeneration in-house power production ensures effective energy utilization and stable plant operation. At the same time, we are looking into ways to further mitigate emissions, such as increasing the proportion of biomass fuels and waste plastics in the co-firing process.

*Power generation efficiency: The net efficiency of a subcritical system is less than 38%, about 38–40% for a supercritical system, and about 41–43% for an ultra-supercritical system. Steam turbine power generation efficiency is increased by raising the temperature and pressure of the steam.

Tosoh Group Greenhouse Gas Emissions Calculation Method

Scope of aggregation

Tosoh: Nanyo Complex, Yokkaichi Complex, Tokyo Research Center, head office/branch offices

Domestic Group companies (34): Hokuetsu Kasei Co., Ltd., Rensol Co., Ltd., Toyo Polymer Co., Ltd., Sankyo Chemical Industry, Inc., Ace Pack Co., Ltd., Tohoku Tosoh Chemical Co., Ltd., Minamikyushu Chemical Industry Co., Ltd., Taiyo Vinyl Corporation, Plas-Tech Corporation, Taihei Chemicals, Ltd., Asia Industry Co., Ltd., Nippon Miractran Co., Ltd., Tosoh Finechem Corporation, Tosoh Hi-Tec, Inc., Tosoh AIA, Inc., Tosoh Hyuga Corporation, Tosoh Ceramics Co., Ltd., Tosoh Zeolum, Inc., Tosoh Silica Corporation, Tosoh Speciality Materials Corporation, Tosoh Quartz Corporation, Tosoh SGM Corporation, Rin Kagaku Kogyo Co., Ltd., Organo Corporation, Organo Food-tech Co., Ltd., Tosoh Logistics Corporation, Koun Industry Co., Ltd., Keiyo Koun Corporation, Koun Marine Co., Ltd., Yokkaichi Koun Corporation, Kansai Kaiun Co., Ltd., Yamaguchi Koun Corporation, Toho Unyu Co., Ltd., Hyuga Unyu Co., Ltd.

Overseas Group companies (18): Tosoh (Guangzhou) Chemical Industries, Inc., Philippine Resins Industries, Inc., Tosoh Polyvin Corporation, Mabuhay Vinyl Corporation, PT. Standard Toyo Polymer, Tosoh (Ruian) Polyurethane Co., Ltd., Tosoh (Shanghai) Polyurethane Co., Ltd., Tosoh Bioscience LLC, Tosoh SMD, Inc., Tosoh SMD Korea, Ltd., Tosoh (Shanghai) Polyurethane Co., Ltd., Tosoh Quartz, Inc., Tosoh Quartz Co., Ltd., Tosoh Quartz Korea Co., Ltd., Tosoh Advanced Materials Sdn. Bhd., Tosoh Hellas Single Member A.I.C., Tosoh Logistics Warehouse Co., Ltd., Oriental Marine Corporation2, 3

- The Yokkaichi Plant is included in the Yokkaichi Complex.

- Logistics companies

- Included in Tosoh Logistics Corporation

Target of calculation

The calculation includes manufacturing and logistics bases of domestic and overseas group companies, and excludes offices located independently.

Calculation method

In the calculation of GHG emissions for fiscal 2022, in addition to the above expansion of the scope of aggregation and handling of calculation targets, the calculation method is based on adjusted GHG emissions. Therefore, the emission factors for electricity are based on adjusted emission factors and do not include waste fuel-derived GHGs, which are listed separately.

*The table can be slid to view.

| Category |

Calculation method |

| Energy usage |

The scope of aggregation encompasses Tosoh Corporation, as well as domestic and overseas group companies. The amount of energy use was calculated based on the Act on the Rational Use of Energy by multiplying the amount of each fuel used, the amount of electricity and steam purchased from outside the group (all physical data) for the relevant fiscal year by the calorific value of each fuel unit specified by the Energy Conservation Law, and converted using a conversion factor (1 gigajoule = 0.0258 kl crude oil equivalent). The calorific value of biofuels was calculated by multiplying the volume of biofuels used in the relevant year (physical data) by the unit calorific value of each fuel.

Unit calorific values for wood are those specified by the Act Concerning the Promotion of the Measures to Cope with Global Warming. Those for other fuels are those obtained individually. |

| Energy-derived CO2 emission volume |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies. Based on the Act on the Rational Use of Energy, the total was the sum of the calculated values from the following equation. |

| × Volume of each fuel used in the relevant year (physical data) X the unit calorific value of each fuel X the emission factor of each fuel |

| × Volume of electricity purchased externally X emission factor for electricity |

| × Amount of steam purchased externally X steam emission factor |

| The unit calorific value and emission factor for each fuel are based on the calculation, reporting, and publication system of the Act Concerning the Promotion of the Measures to Cope with Global Warming. Emission coefficients for electricity in Japan are based on values for each electric utility for the relevant year. Emission factors for overseas electricity are the fiscal 2020 values for each country listed in the 2021 edition of Emissions Factors published by the International Energy Agency (IEA). The emission factor for overseas steam is the value from Citation 1. |

| Non-energy-derived CO₂ emissions and GHG emissions other than CO₂ |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies. Calculation method, unit calorific value, emission factor, and global warming potential are based on the calculation, reporting, and publication system of the Act Concerning the Promotion of the Measures to Cope with Global Warming. |

| Scope 3 |

Calculated based on the following concept: [activity level] x [emission factor]. |

| Scope 3: Greenhouse Gas Emissions |

Category 1: Purchased goods and services |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies (excluding logistics group companies).

Activity level: Volume of major raw materials procured externally by each Group company (total amount is shown in the Input/Output section of the Tosoh Report) (physical data)

Emission factors: Citation 1

Logistics group companies

Activity level: Repair costs

Emission factors: Citation 2 |

|

|

|

|

|

|

| Category 2: Capital goods |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies.

Activity level: Asset value of buildings and structures, machinery and equipment, ships, vehicles, tools, furniture, fixtures, and land purchased or acquired during the fiscal year (financial data)

Emission factors: Citation 2 |

|

|

|

|

| Category 3: Fuel and energy-related activities not included in Scopes 1 and 2 |

The scope of aggregation encompasses Tosoh Corporation as well as domestic and overseas group companies.

Activity level: Fuel consumption by Tosoh Corporation and Group companies, electricity and steam purchased externally (physical data)

Emission factors: Emission factors for fuel are from Citation 1, and from Citation 2 for electricity and steam fuel procurement. |

|

|

|

|

| Category 4: Transportation and delivery (upstream) |

The scope of aggregation encompasses Tosoh Corporation, domestic group companies (excluding Organo Corporation, Organo Food-tech Co., Ltd., and logistics group companies), and overseas group companies (excluding Tosoh Bioscience LLC and logistics group companies).

1) Transportation of raw materials

Activity level: Volumes (physical data) of major raw materials used by Tosoh Corporation and Group companies (total volumes are shown in the Input/Output section on the website (Environmental Protection)), and transportation distances from the suppliers of each raw material to Tosoh Corporation and Group companies.

× Assumed standard transportation distances for domestic procurement: 500 km for land, and 1,000 km for marine

× For international marine transportation, values from Citation 1 are used for transportation distances

Emission factors: Citation 1

2) Product delivery

1. Domestic transportation

× Tosoh Corporation: Reported values under the Act on the Rational Use of Energy and the Known Shipper/Regulated Agent system

× Group companies

Activity level: Product shipment volume (quantity data) and transportation distance for each Group company. Assumes uniform standard transportation distances of 500 km for land and 1,000 km for marine.

Emission factors: Citation 1

2. International Transportation

Activity level: Product shipment volume (physical data) and transportation distance for Tosoh Corporation and Group companies. Transportation distances are based on the values in Citation 1.

Emission factors: Citation 1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Category 5: Waste generated by business activities |

The scope of aggregation includes Tosoh Corporation and domestic Group companies.

Activity level: Industrial waste generated by Tosoh and domestic Group companies and incinerated, landfilled, or recycled externally (based on volume)

Emission factors: Citation 2 |

|

|

|

|

| Category 6: Business trips |

The scope of aggregation includes Tosoh Corporation, as well as domestic and overseas Group companies.

Activity level: Tosoh's business travel expenses for the fiscal year (categorized as domestic travel and transportation expenses (rail), domestic taxi expenses, and international travel and transportation expenses (international air travel)) (financial data )

Calculations for Group companies are based on a comparison of the number of employees to that of Tosoh Corporation, and used as representative values.

Emission factors: Citation 2 |

|

|

|

|

|

| Category 7: Employee commuting |

The scope of aggregation encompasses Tosoh Corporation, as well as domestic and overseas Group companies.

Activity level: Tosoh's commuting expenses (categorized into commuter pass (rail) and gasoline (private car)) for the relevant fiscal year (financial data)

Calculations for Group companies are based on a comparison of the number of employees to that of Tosoh Corporation, and used as representative values.

Emission factors: Values for railroads are from Citation 2, and values for private cars are from Citation 1. |

|

|

|

|

|

| Category 8: Leased assets (upstream) |

× Emissions from product transportation are calculated in Category 4.

× Downstream emissions other than those generated during product transportation are excluded from the calculation because it is difficult to reasonably calculate emissions from diverse, complex transportation and delivery modes. |

|

| Category 9: Transportation and delivery (downstream) |

× Emissions from product transportation are calculated in Category 4.

× Downstream emissions other than those generated during product transportation are excluded from the calculation because it is difficult to reasonably calculate emissions from diverse, complex transportation and delivery modes. |

|

| Category 10: Processing of products sold |

The Tosoh Group's products are primarily materials and components, which undergo a variety of processing before reaching end users. This renders it difficult to reasonably estimate the type and scale of processing methods. Therefore, they are excluded from the calculation in accordance with the World Business Council For Sustainable Development (WBCSD) Guidance for Accounting & Reporting Corporate GHG Emissions in the Chemical Sector Value Chain. |

|

| Category 11: Use of products sold |

The scope of aggregation encompasses Tosoh Corporation.

Assuming that the butane fraction of the product is used as fuel

Activity level: Sales volume of recovered residual oil (physical data)

Emission factors: Value set in the Act on Promotion of Global Warming Countermeasures |

|

|

|

|

|

| Category 12: End-of-life treatment of products sold |

The scope of aggregation encompasses Tosoh Corporation, as well as domestic Group companies (excluding Organo Corporation, Organo Food-Tech Co., Ltd., and logistics group companies), and overseas Group companies (excluding Tosoh Bioscience LLC and logistics group companies).

The final product in which the products of Tosoh Corporation and its Group companies are used as raw materials is estimated, and it is assumed that all of the products produced by the Group in the relevant fiscal year became waste. In accordance with the WBCSD Guidance for Accounting & Reporting Corporate GHG Emissions in the Chemical Sector Value Chain, the carbon content in waste petroleum products, solvents, and resins was set at 80% by weight, with 80% landfilled and 20% incinerated.

Activity level: Production volume (excluding consumption within the Group) (based on volume)

Emission factors: Citation 2 |

|

|

|

|

|

| Category 13: Leased assets (downstream) |

Since the assets are minimal, they are excluded from the calculation as the associated emissions impact is negligible. |

|

| Category 14: Franchises |

There are no applicable emissions because the company does not engage in a franchise business. |

|

| Category 15: Investments |

Tosoh's holdings in each non-Group company are intended to maintain and develop business relationships, and are limited to key customers and suppliers. The scale of each company’s GHG emissions multiplied by the shareholding ratio of Tosoh Corporation to the shares of each company is regarded as small, and as the impact on the Tosoh Group is considered to be negligible, it was excluded from the calculation. |

|

Emission factor citation database

Citation 1: IDEA LCA Database (National Institute of Advanced Industrial Science and Technology (AIST), Sustainable Management Promotion Organization (SuMPO))

→ Ver. 2.2 until FY2019, ver. 2.3 from FY2020 onward

Citation 2: Emission intensity database for calculation of greenhouse gases and other emissions of organizations through the supply chain (Japan's Ministry of the Environment, Ministry of Economy, Trade and Industry)

→ Ver. 2.6 until FY2019, ver. 3.0 in FY2020, ver. 3.1 in FY2021, and ver. 3.2 in FY2022.

Environmental Protection

| Key Performance Indicators (KPIs) |

FY2022 Targets |

FY2022 Results |

Appraisal |

| 1) Number of incidents of violation of environmental laws and regulations/agreements |

Zero |

Zero |

Achieved |

| 2) Number of deviations from regulatory/agreed values |

Zero |

Two (regulatory/agreed values) |

Not achieved |

|

| 3) Reduction of PRTR-applicable substance emissions |

424 metric tons or less (30% reduction compared with fiscal 2016) |

413 |

Achieved |

| 4) Reduction of landfill industrial waste |

1,000 metric tons or less |

649 |

Achieved |

| 5) Promotion of disposal of equipment containing PCBs |

Low-concentration PCB equipment planned disposal |

Implemented as planned |

Achieved |

Basic Concept

Through its business activities, the Tosoh Group contributes to the development of a sustainable society in which the environment, economy, and society are in integrated harmony, and strives to achieve a recycling economy, including the effective use of resources.

We aim to minimize environmental impact by properly managing important control items such as air and water emissions and waste generated by our business activities.

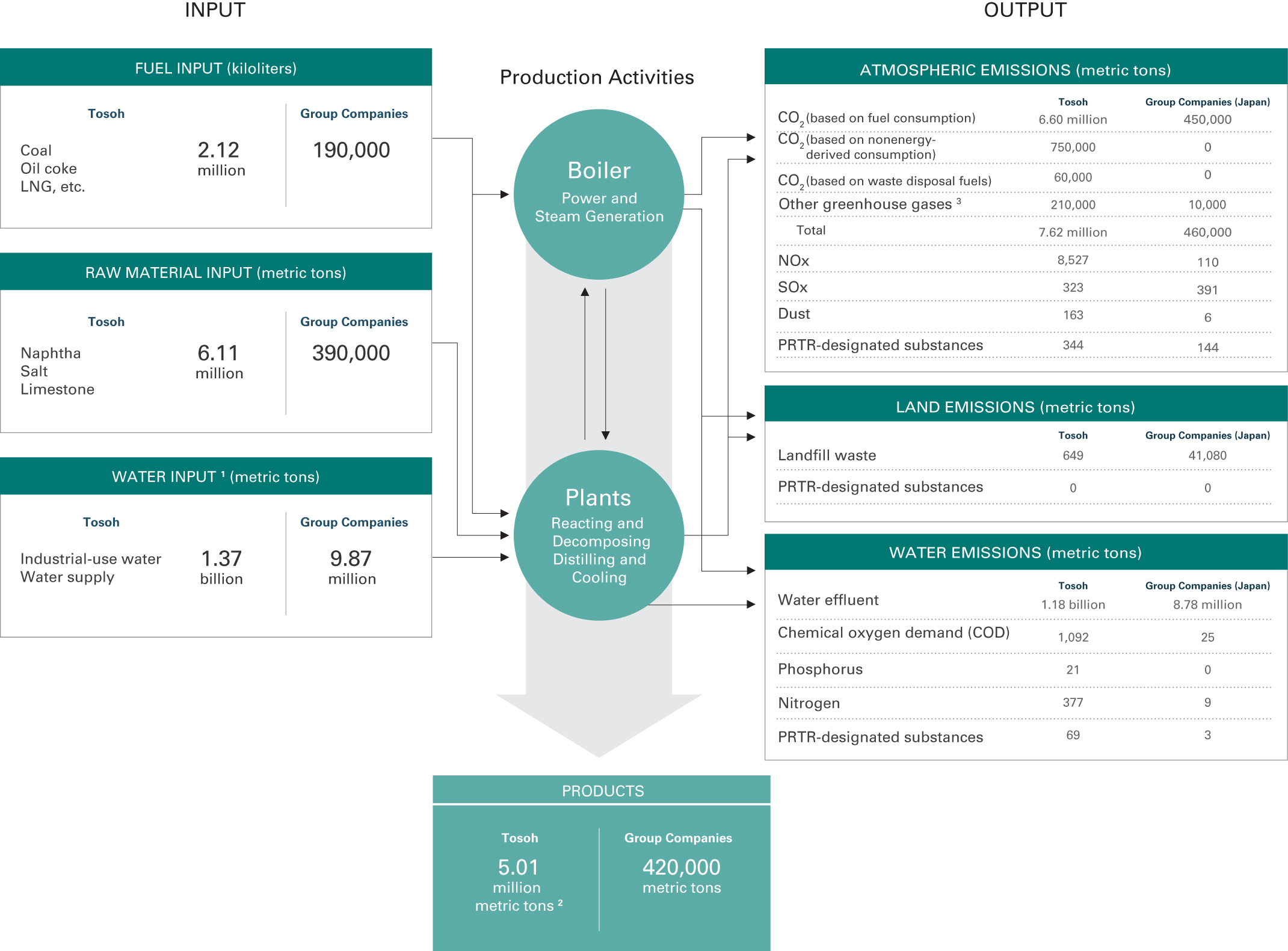

Input/Output (Tosoh Group)

The Tosoh Group reduces the environmental impact of its business activities throughout the lifecycle of its products. In addition, we make effective use of the input of limited resources—or “inputs” such as fuel, raw materials, and water resources—to obtain products, and strive to minimize waste “outputs” and the extent of the company’s environmental impact on the air and water.

Tosoh and Domestic Group Companies

Please refer to the list here for the scope of aggregation.

Group Companies (overseas)

Please refer to the list here for the scope of aggregation.

Atmosphere Preservation

Tosoh and its group companies in Japan monitor the concentration and amount of sulfur oxides (SOx), nitrogen oxides (NOx), soot and dust, and other air pollutants emitted by each specific facility. We set voluntary control values that are stricter than those set by Japan’s Air Pollution Control Act and those agreed upon with local governments.

At certain factories, SOx in exhaust gas is discharged into the atmosphere after being collected through desulfurization, NOx through catalytic adsorption, and dust through electrostatic precipitation, in the interest of protecting the air environment.

In fiscal 2022, there were no instances in which regulatory and agreed-upon values were exceeded.

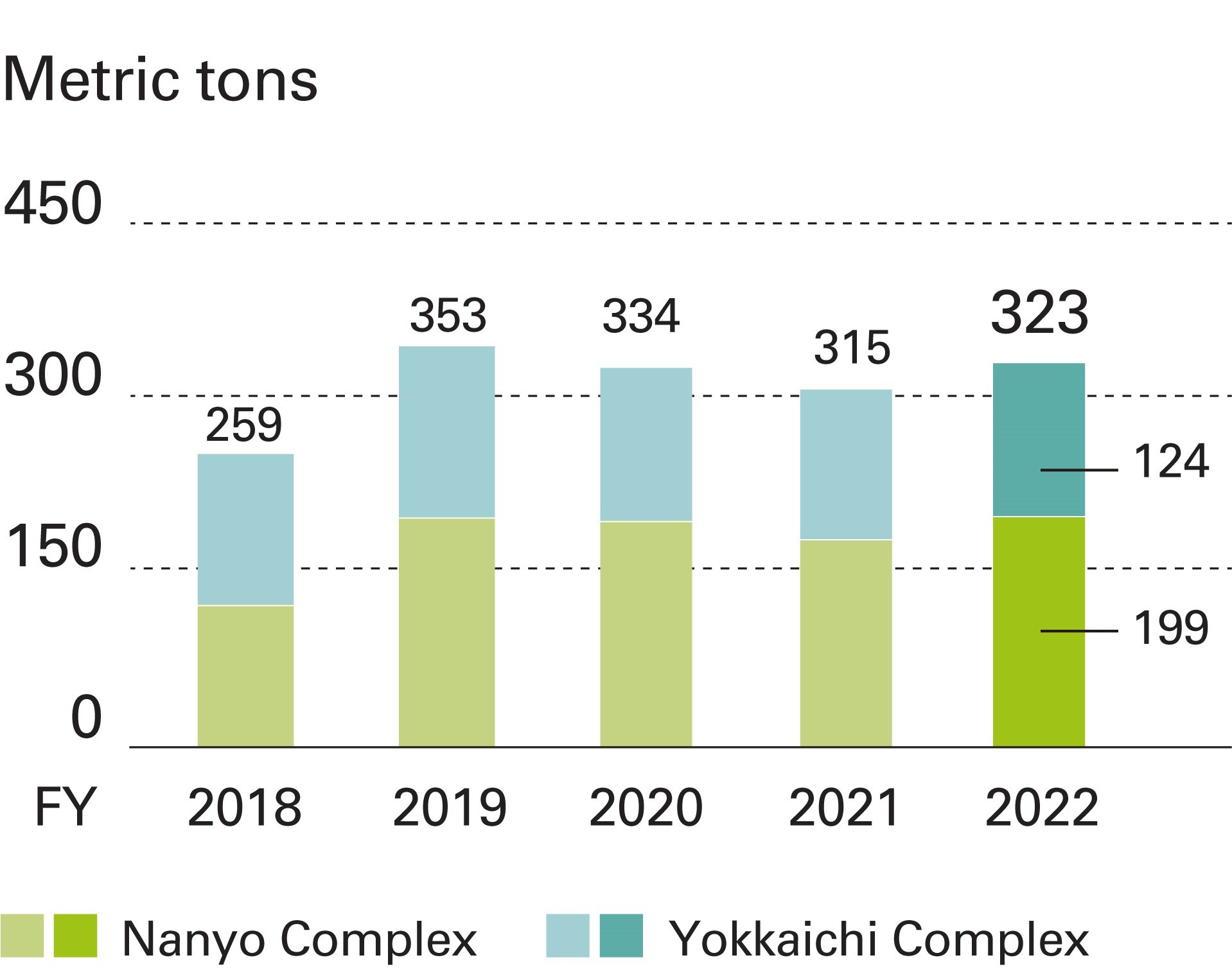

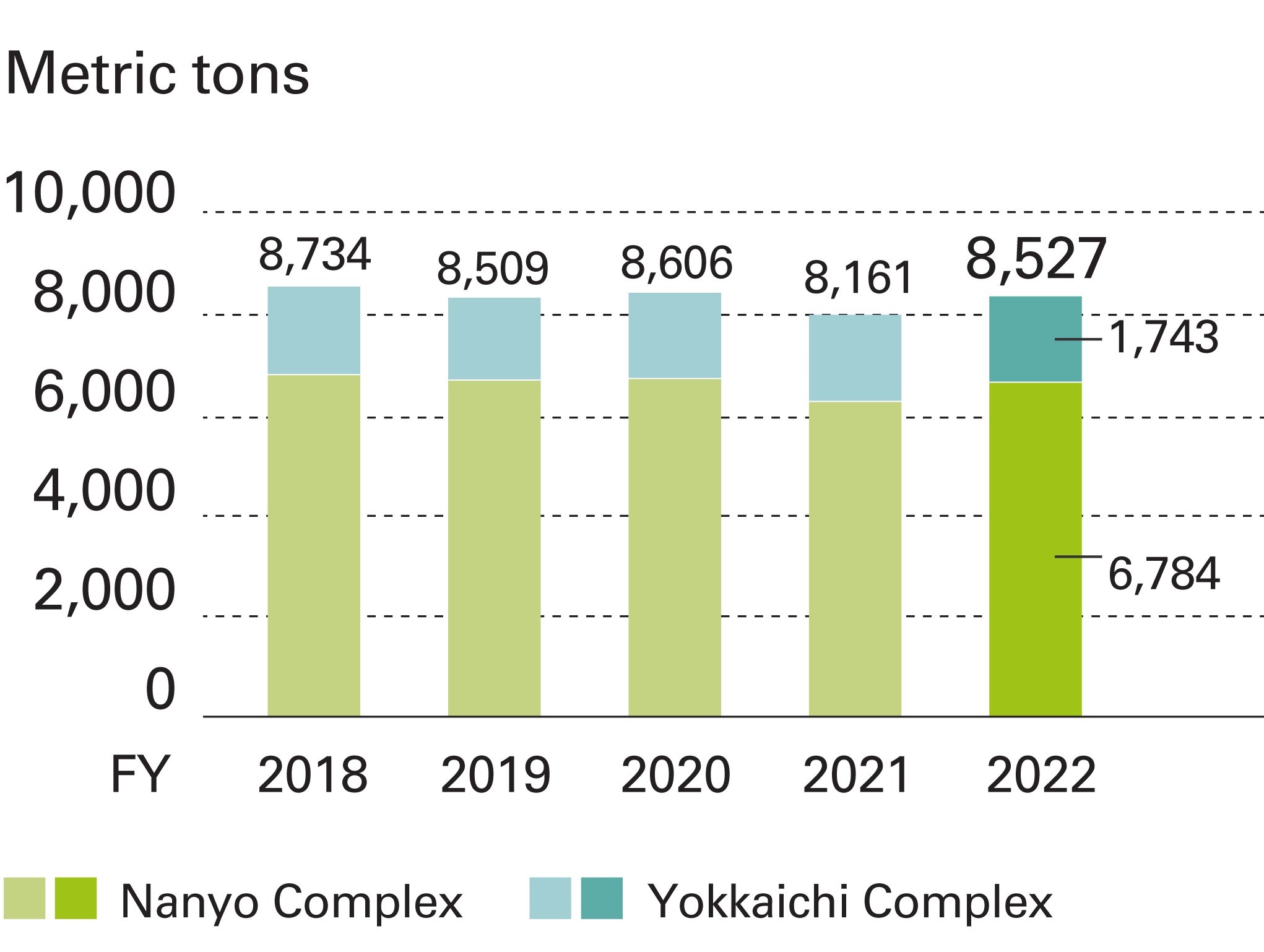

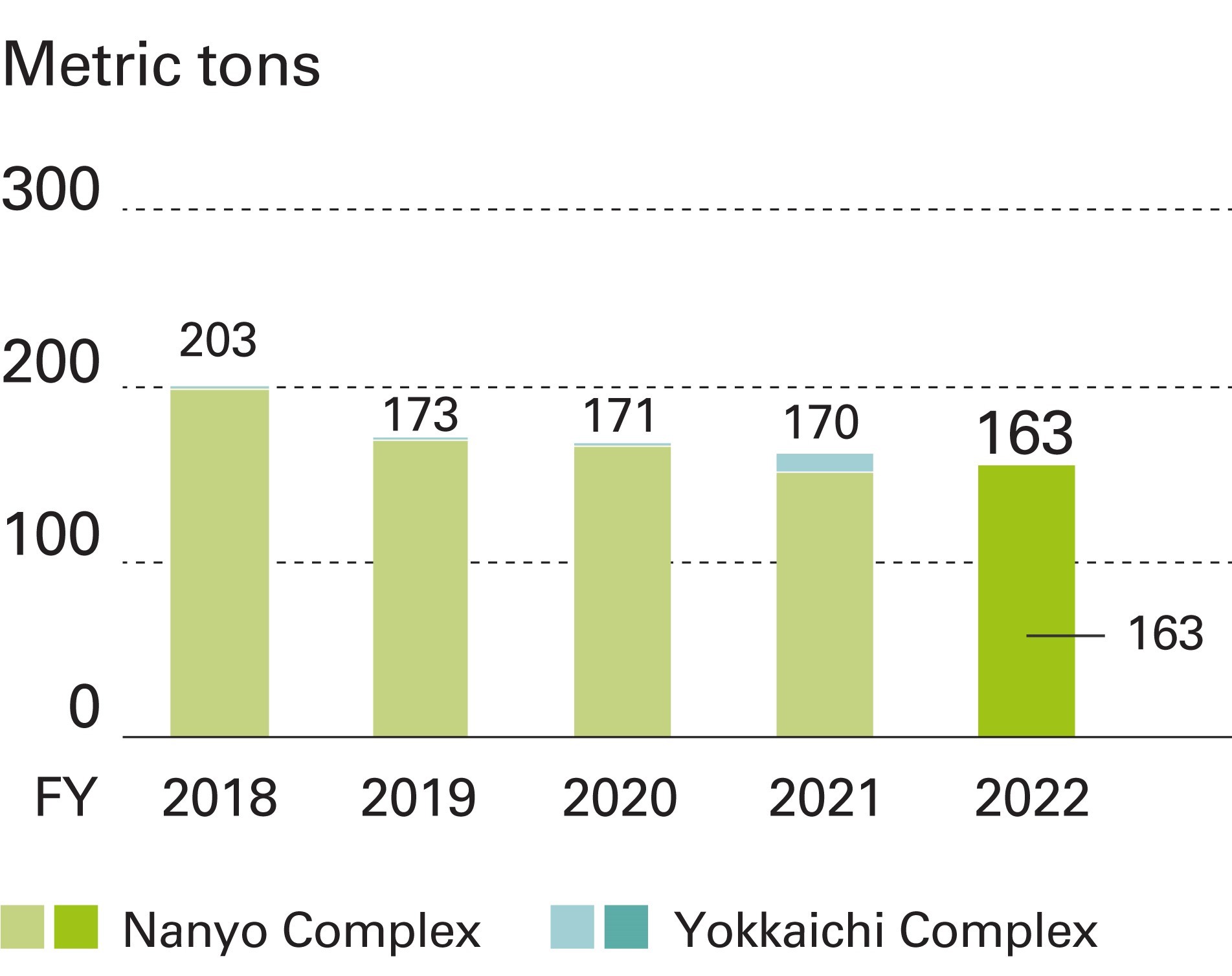

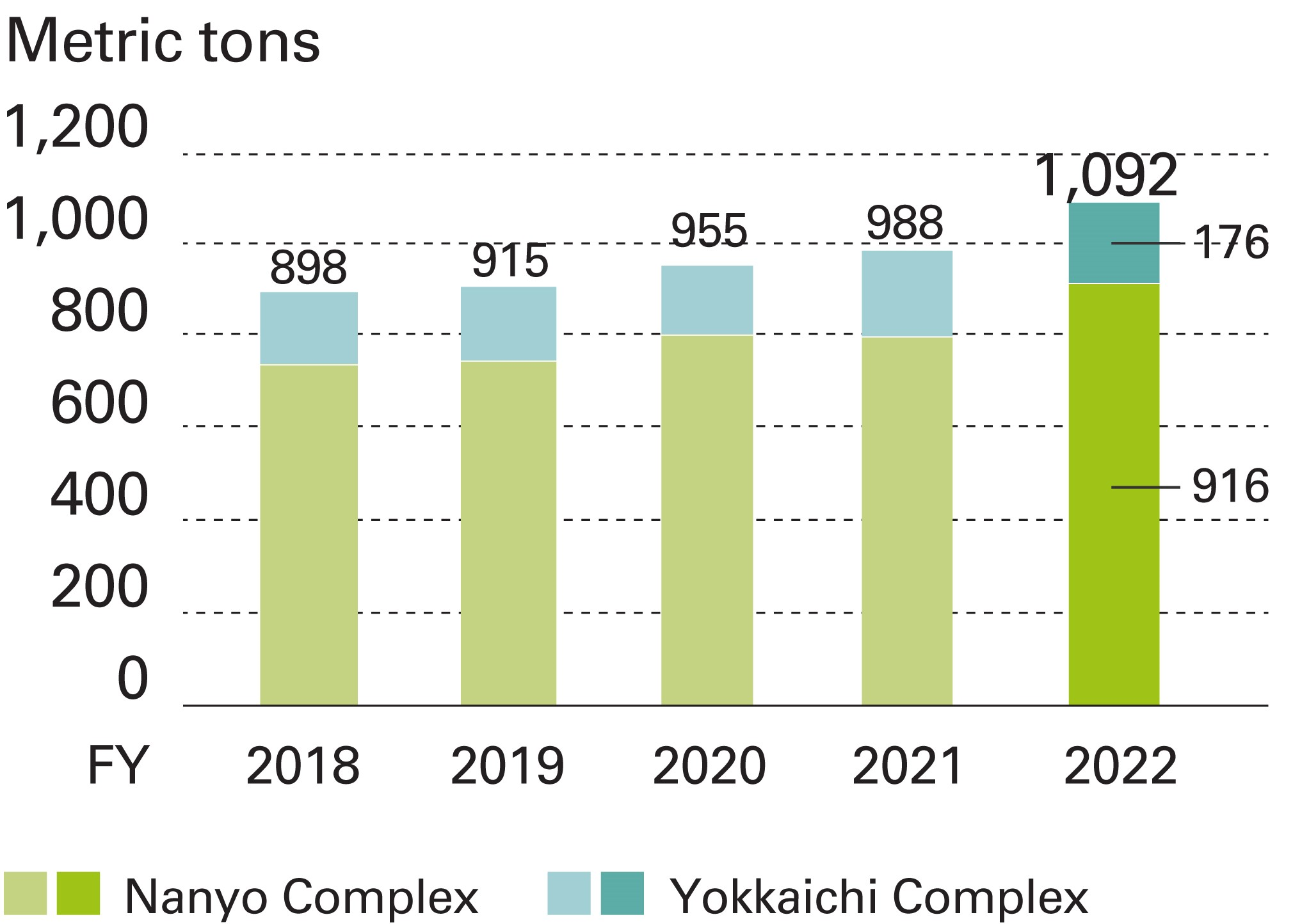

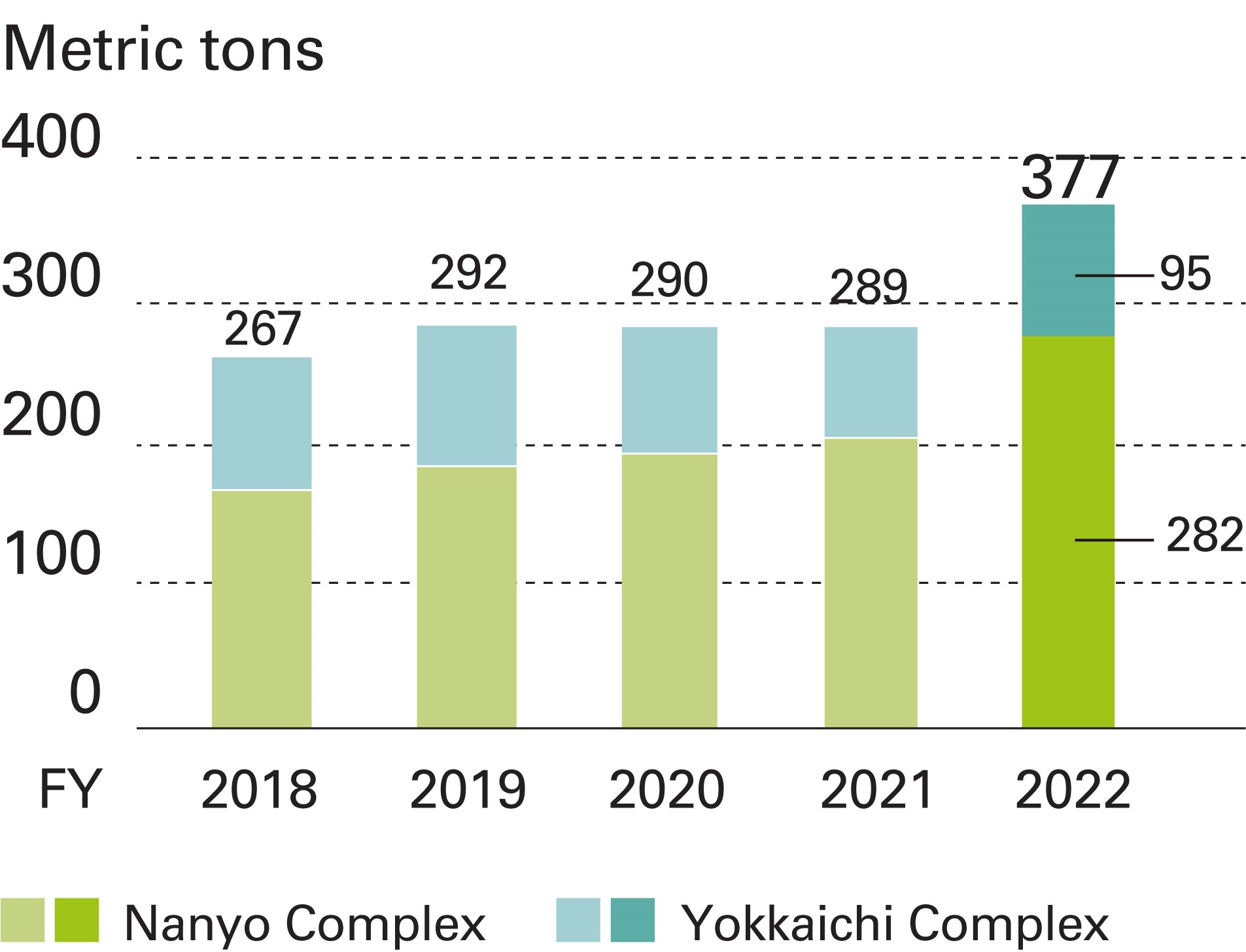

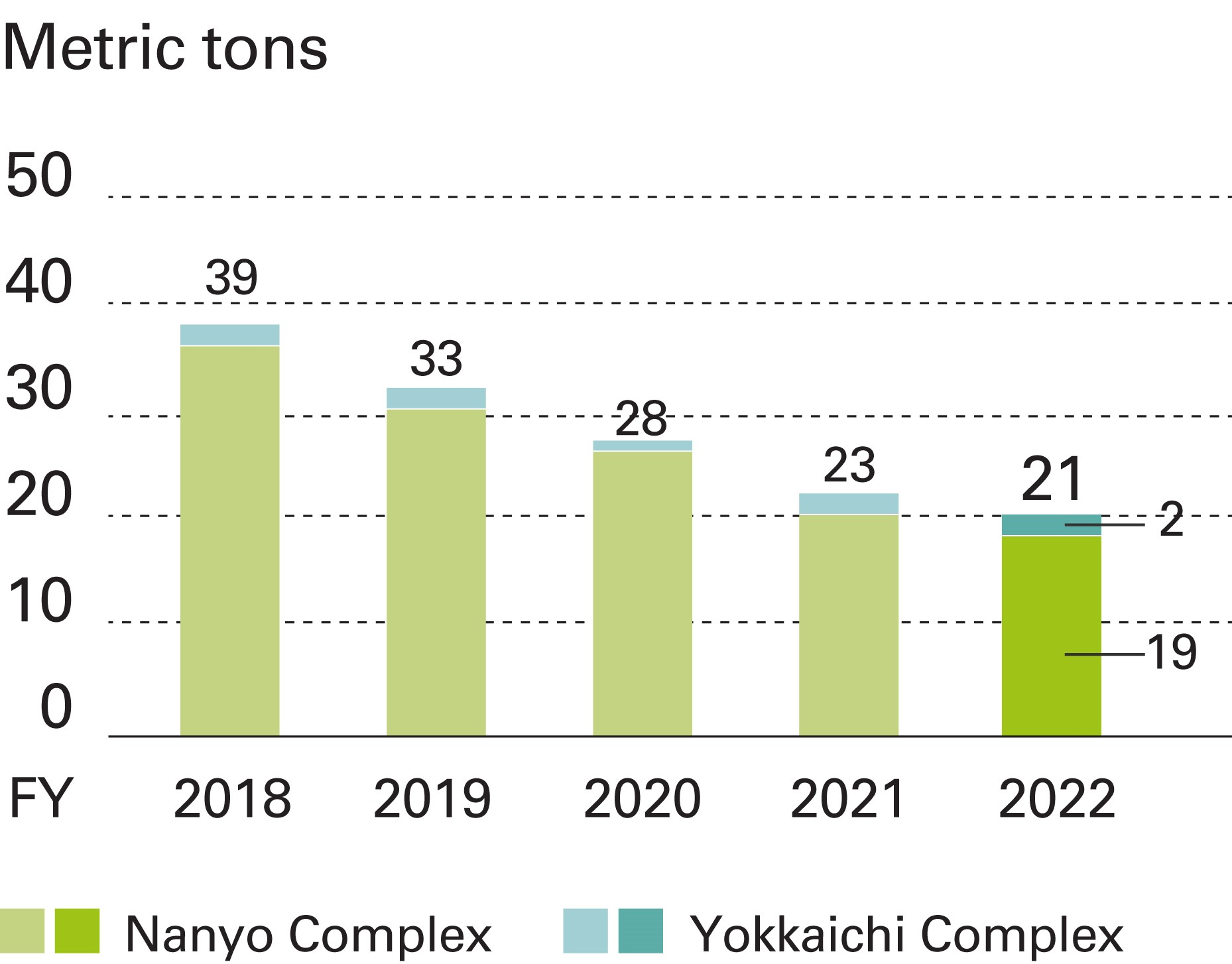

SOx Emission Volume

NOx Emission Volume

Dust Emission Volume

Calculation method: Calculated from analysis values (concentration and gas emissions) at each legally specified time for each specific facility.

Volatile Organic Compounds (VOCs)

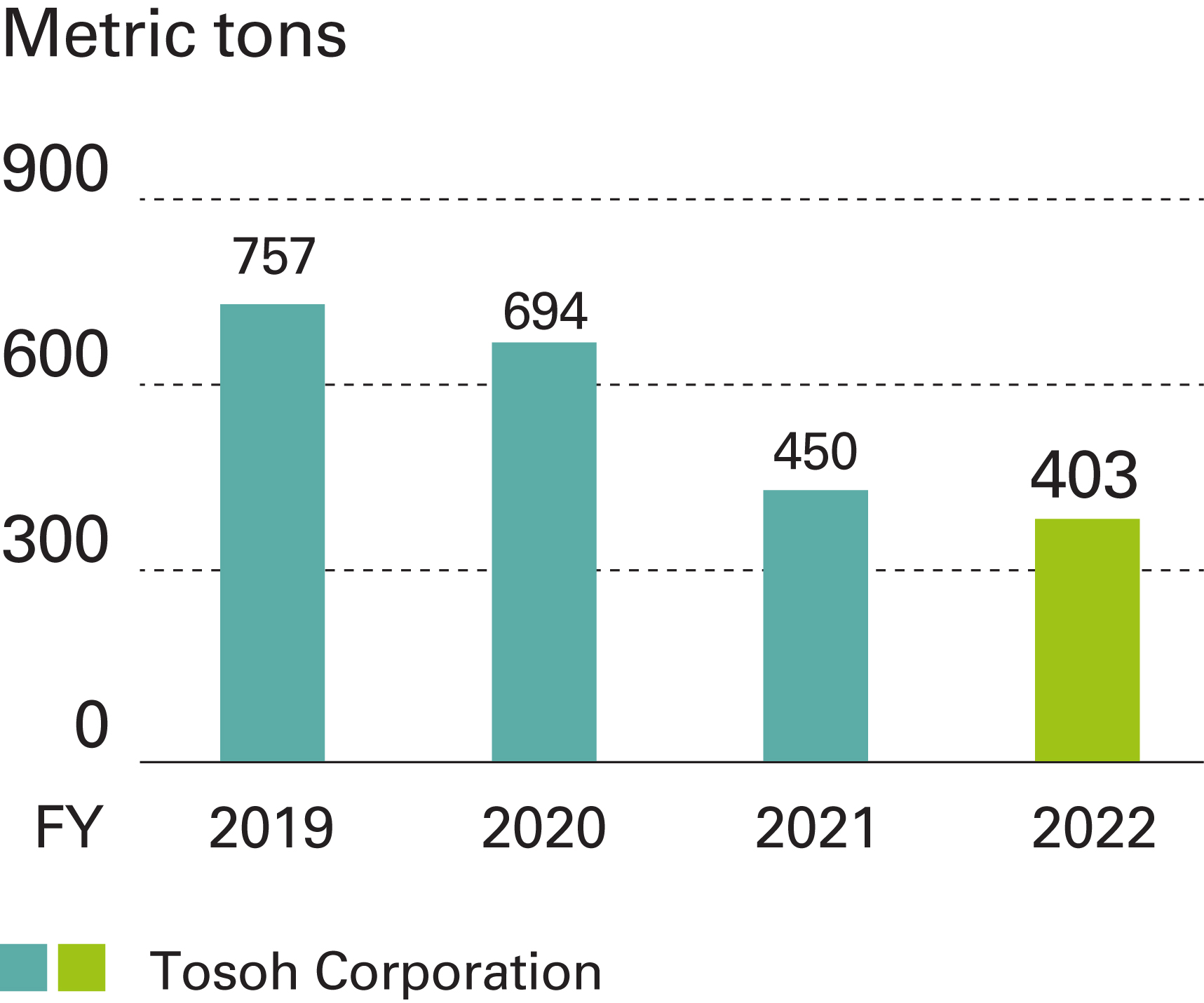

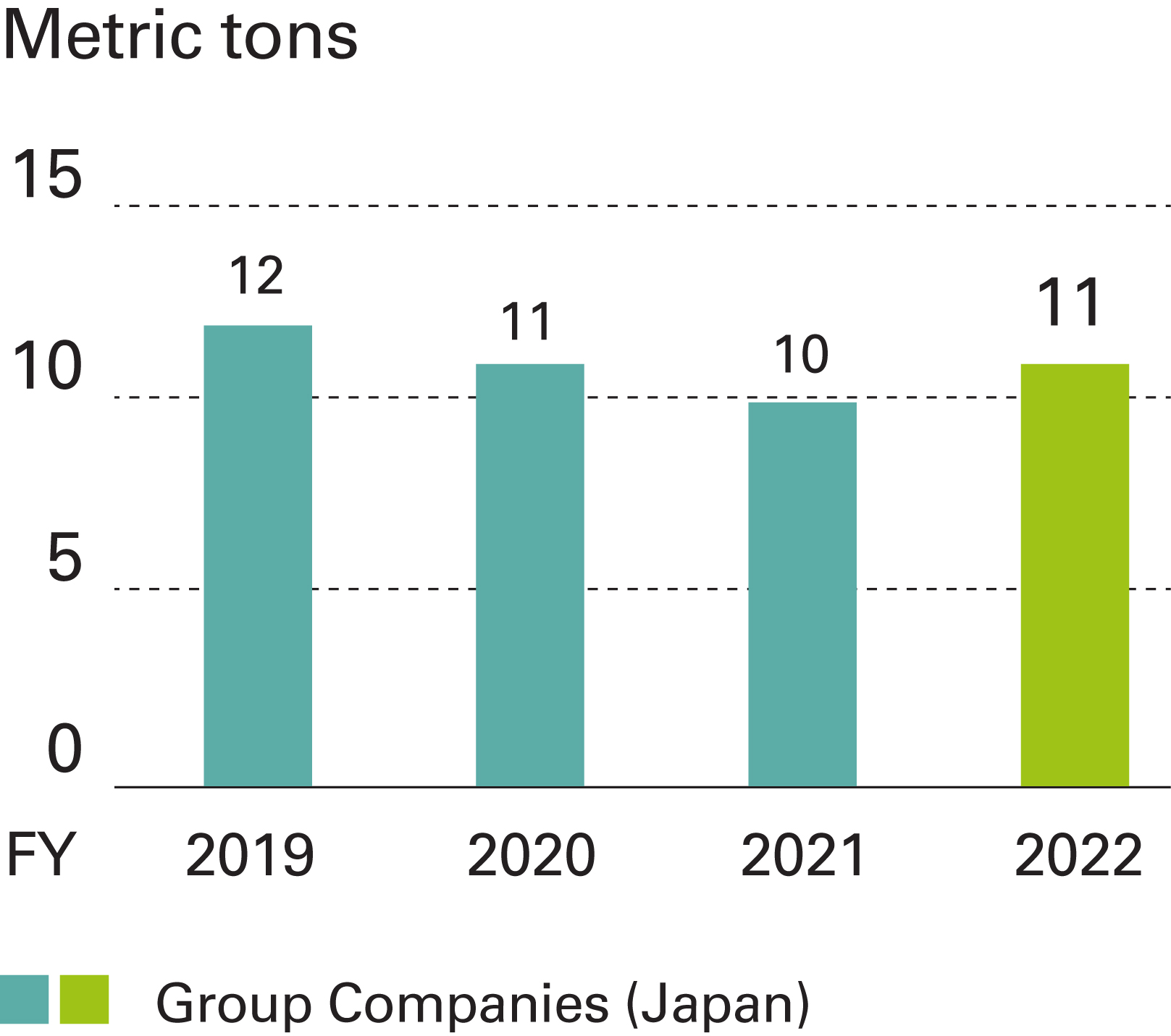

Tosoh's VOC emissions were 403 tons in fiscal 2022. Meanwhile, the total for domestic group companies was 11 tons.

Group companies (Japan)

Specified Chlorofluorocarbons (CFCs)

Tosoh is taking action on equipment that uses specified chlorofluorocarbons (CFCs and HCFCs) as refrigerants based on environmental laws and regulations (Act on the Protection of the Ozone Layer through Regulation of Designated Substances) and administrative guidelines and trends.

Moreover, in accordance with the Act Concerning the Discharge and Control of Fluorocarbons, we properly report the volume of calculated leaks of CFC substitutes to the government, and we establish management targets to minimize leaks and promptly implement repair measures through early detection of leaks using detection equipment.

Water Preservation

Tosoh and its Group companies in Japan remove pollutants from wastewater at wastewater treatment facilities, recover active ingredients in wastewater, and monitor emissions of COD, nitrogen, phosphorus, and other substances by setting voluntary control values that are stricter than those stipulated by the Water Pollution Control Law and agreements with local governments.

In fiscal 2022, there were two cases in which regulatory limits were exceeded (no penalties or administrative guidance were issued).

COD Emission Volume

Nitrogen Emission Volume

Phosphorus Emission Volume

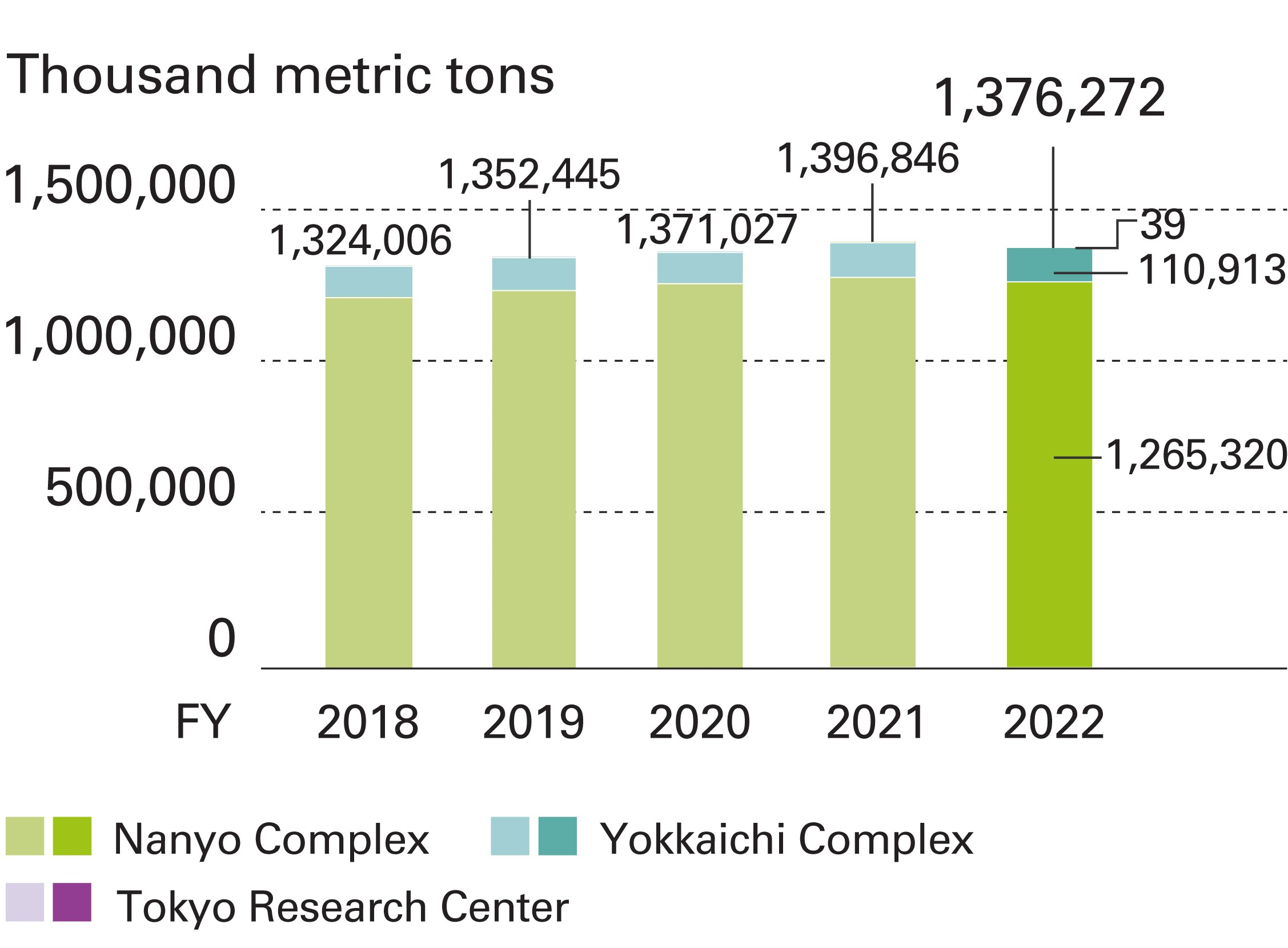

Water Resource Utilization

Tosoh and its group companies in Japan manufacture a wide variety of chemical products and use water in manufacturing. This includes processes such as heating, cooling, dissolving, and washing, as well as at chemical detoxification and drainage facilities.

For this reason, water is an essential resource for the Tosoh Group. Each Group company strives to make effective use of water intake (circulating water cooling systems, higher performance heat exchangers) and to maintain and improve wastewater quality with the aim of sustainable utilization of water resources in the vicinity of its business sites.

We also require our suppliers to manage wastewater and use water efficiently through our CSR procurement guidelines.

The Tosoh Group uses tools to conduct water risk assessments for each of its manufacturing sites in Japan and abroad. The results confirm that the water risk at each site is relatively low.

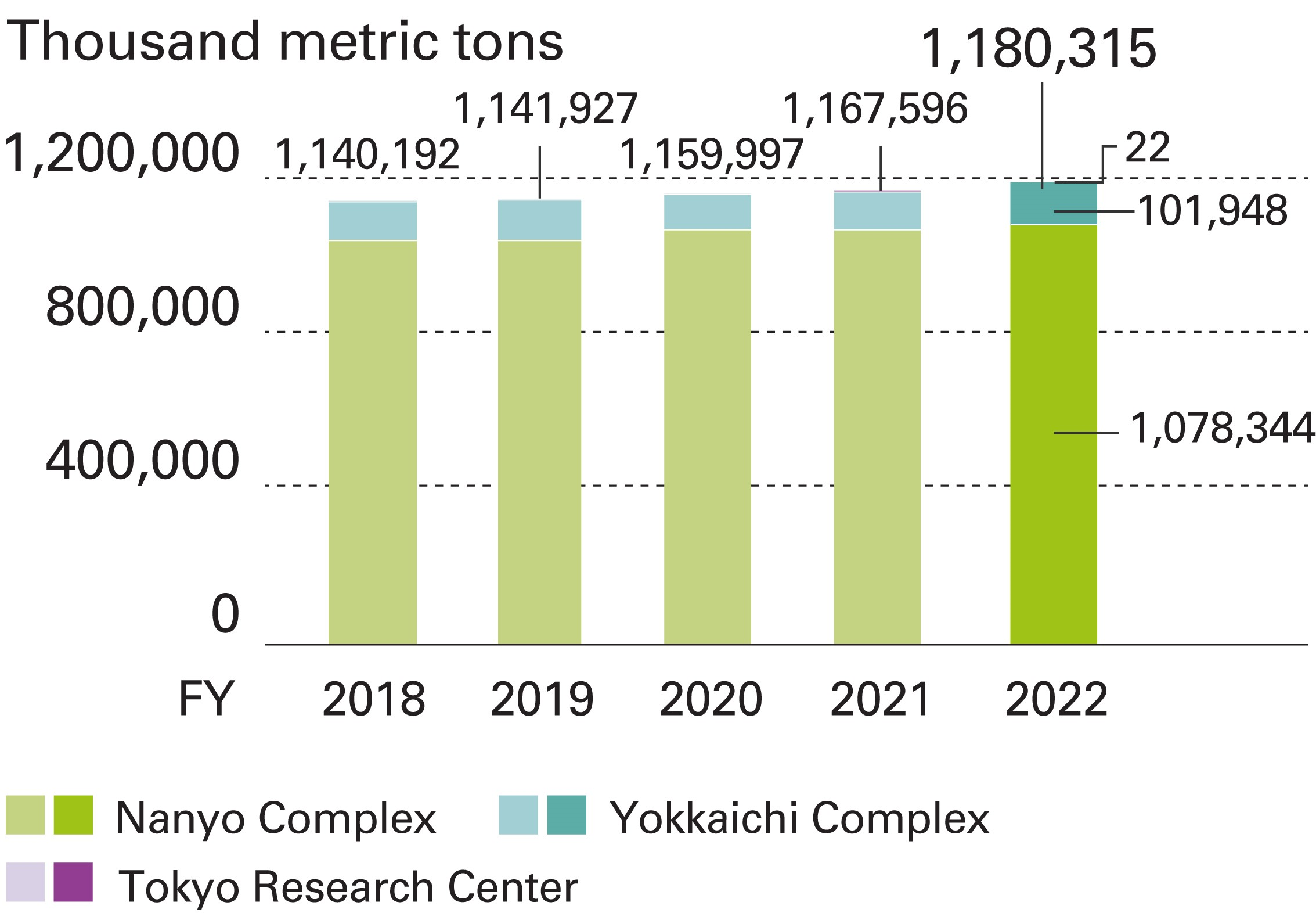

Water Input Volume

Effluent Volume

Industrial Waste

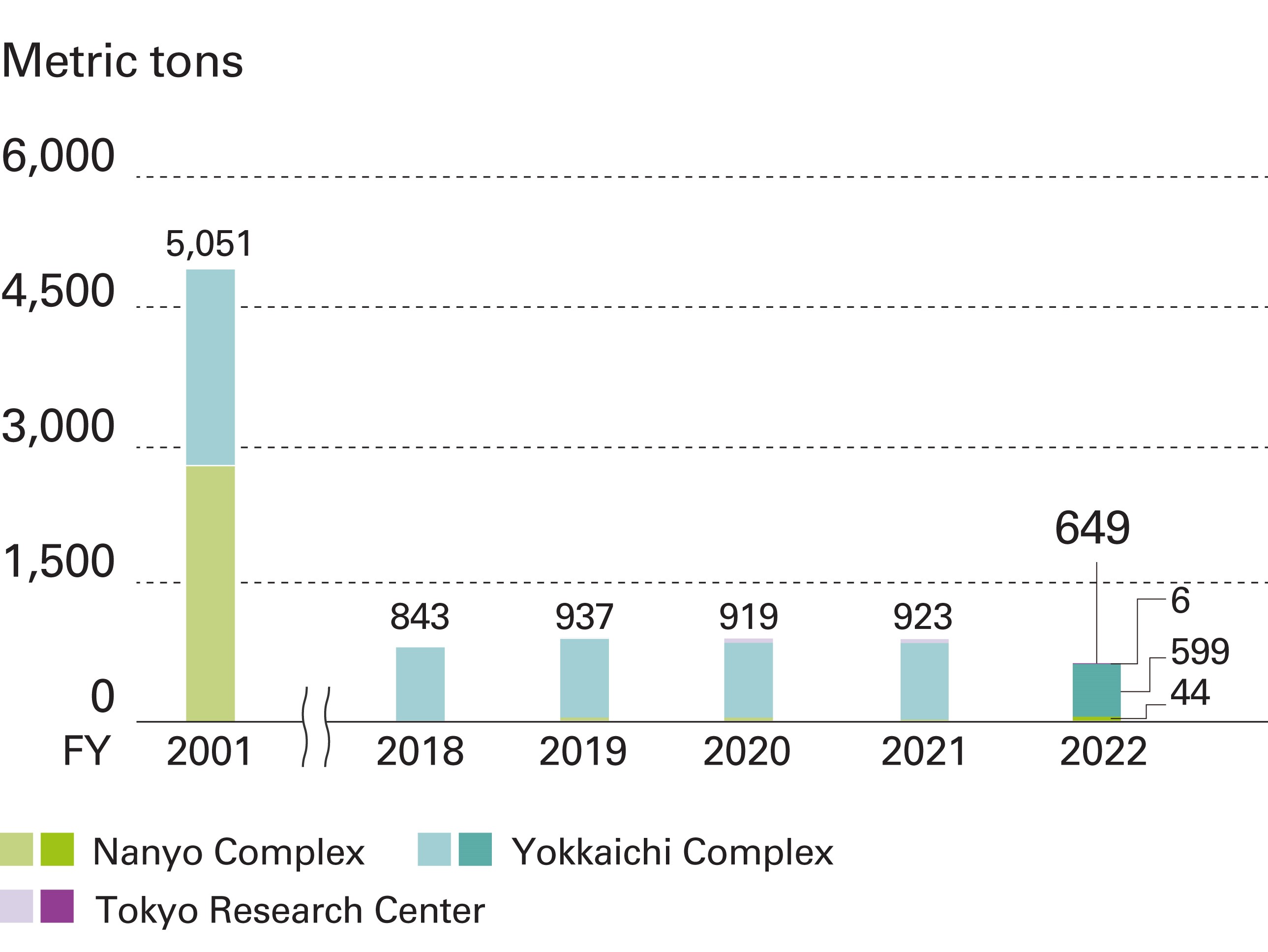

Tosoh and its group companies in Japan are promoting the 4Rs—reduce, reuse, recycle, and renew—in support of the transition to a circular economy. Tosoh has established the objective of reducing the volume of final disposal by approximately 75% from the fiscal 2001 actual level, in accordance with the fifth target of Keidanren’s Voluntary Action Plan for Establishing a Sound Material-Cycle Society.

Final disposal volume in fiscal 2022 was 649 tons, achieving the target (1,000 metric tons or less). Most of the coal ash and other industrial waste generated at our business sites is recycled as raw materials for use at cement plants. We also promote "local production for local consumption" recycling of plastic waste collected from municipalities and actively accept external plastic waste for effective use as raw fuel for cement. This contributes to reducing the burden on the surrounding community.

Aware of their responsibilities as generators of waste, Tosoh Group companies also manage and dispose of waste properly until it is delivered to a disposal company.

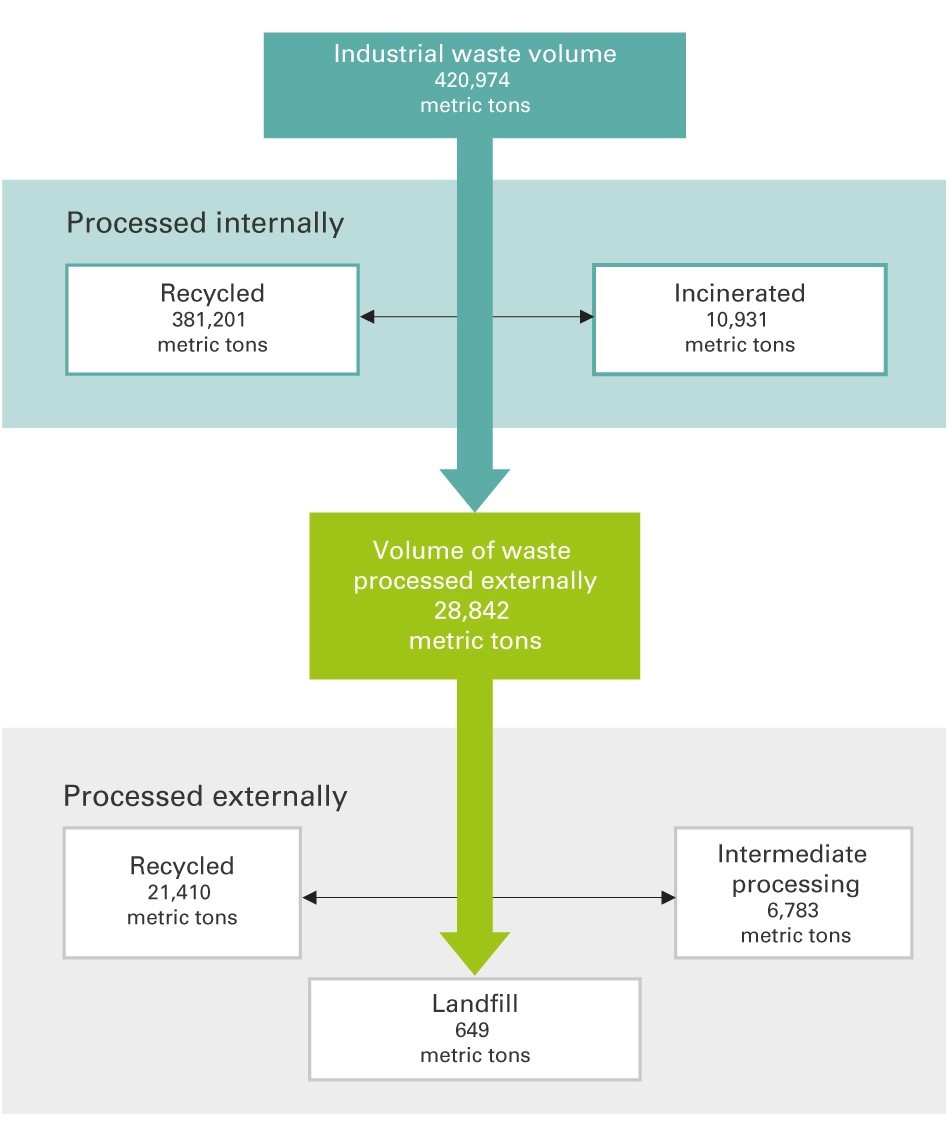

Industrial Waste Processing Flow (excluding specially controlled industrial waste)

Data collection method: Data is aggregated from volume data recorded in the manifest.

Of the amount of externally processed waste, 3,243 metric tons (specified hazardous industrial waste* 1,166 metric tons, other 2,077 metric tons) are specified as hazardous.

The values given are totals for the Nanyo Complex, Yokkaichi Complex, and Tokyo Research Center.

Final disposal volume in FY2022 was 0.15% of total industrial waste generated.

*Specific hazardous industrial waste: Waste containing PCBs, waste mercury, waste asbestos, toxic metals, etc. (cadmium, lead, chromium, arsenic, dioxins, waste oil, etc.)

Final Landfill Disposal Volume

To improve accuracy, data is corrected retroactively.

Status of Disposal of Equipment Containing PCBs

Tosoh and its Group companies in Japan are promoting the appropriate disposal of equipment containing polychlorinated biphenyls (PCBs) in accordance with Japan’s PCB Special Measures Law. Tosoh completed disposal of equipment containing high concentrations of PCBs, including transformers and capacitors, by fiscal 2018. Disposal of all equipment containing high concentrations of PCBs, including lighting ballasts, has been completed, as of fiscal 2021. Approximately 50% of all equipment containing low-concentration PCBs were disposed of in fiscal 2022, with the remaining equipment to be disposed of systematically by fiscal 2027.

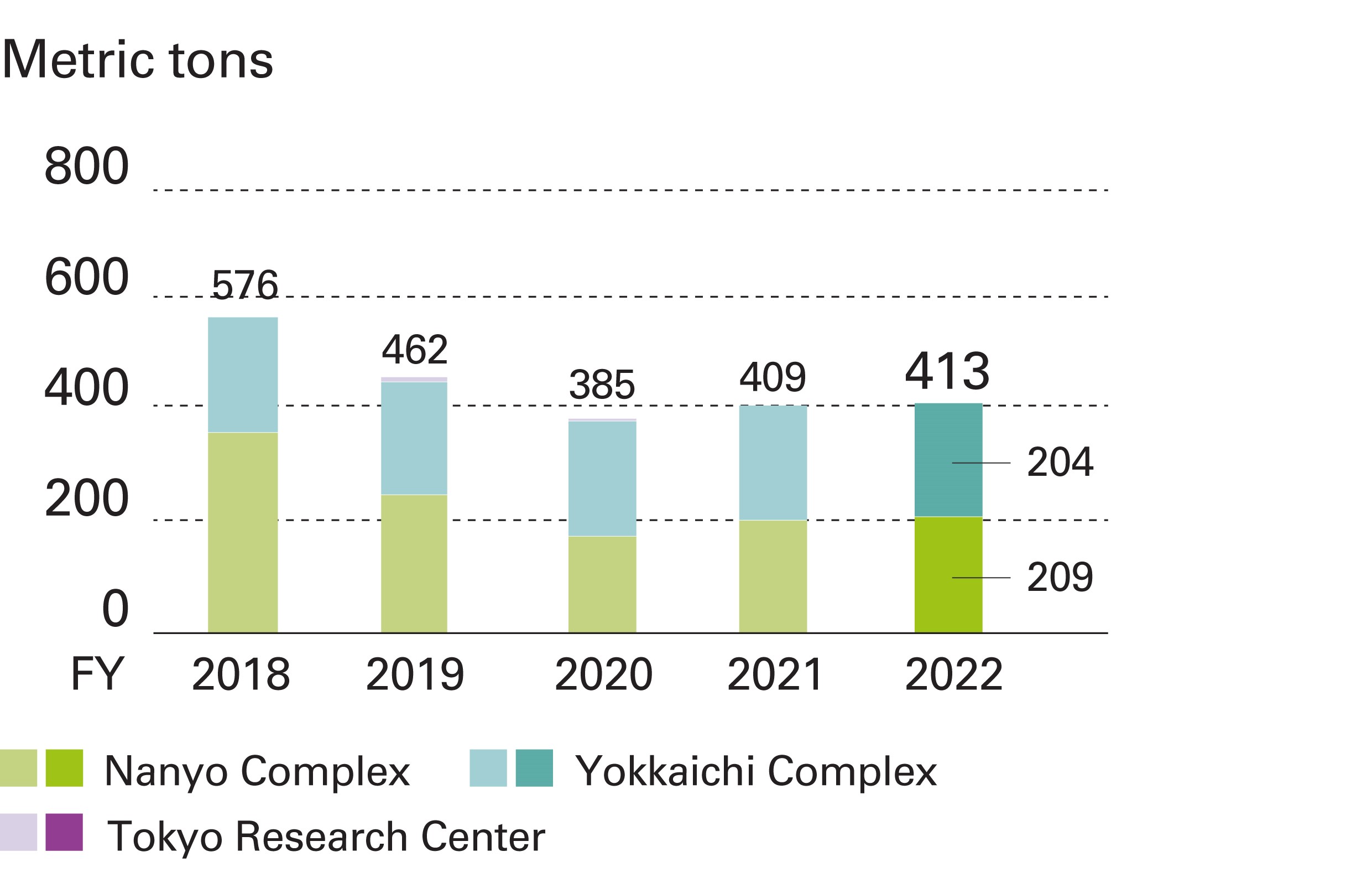

Emission Reduction Measures for Substances Subject to PRTR System

Tosoh and its group companies in Japan have set voluntary emission reduction targets for substances subject to Japan’s Pollutant Release and Transfer Register (PRTR) system based on the Act for Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvements to the Management Thereof (Law concerning Pollutant Release and Transfer Register). Tosoh achieved its target (424 tons or less: a reduction of 30% or more from the fiscal 2016 level), with 413 metric tons of emissions in fiscal 2022. Meanwhile, the total emissions of domestic Group companies amounted to 147 metric tons, an increase of 30 metric tons from fiscal 2021.

Total Emissions of PRTR-Applicable Substances

Calculation method: Based on the calculation method of the Law concerning Pollutant Release and Transfer Register for each target substance.

Emissions and Transfers of PRTR Substances in FY2022

| Substance |

Atmospheric

emission volume |

Water effluent

volume |

Land emission

volume |

Landfill disposal

volume |

Emission volume

within complexes |

Amount transferred to

sewage system |

Amount transferred

out of complexes |

|

| Chlorobenzene |

38.8 |

0.9 |

0 |

0 |

39.7 |

0 |

42.1 |

| Chloroethylene (vinyl chloride) |

60.3 |

2.1 |

0 |

0 |

62.4 |

0 |

0 |

| Chloroform |

1.6 |

10.8 |

0 |

0 |

12.4 |

0 |

0.4 |

| 1,2-Dichloroethane |

29.6 |

1.7 |

0 |

0 |

31.3 |

0 |

37.6 |

| Ethylenediamine |

3 |

11.5 |

0 |

0 |

14.5 |

0 |

0 |

| Vinyl acetate |

11.5 |

7.4 |

0 |

0 |

18.9 |

0 |

0 |

| 1,1,2-Trichloroethane |

9.5 |

0.6 |

0 |

0 |

10.1 |

0 |

30.3 |

| N-hexane |

152.1 |

0.3 |

0 |

0 |

152.4 |

0 |

1.6 |

| Other |

37.4 |

34.1 |

0 |

0 |

71.5 |

0 |

1,115.30 |

| Dioxins (mg-TEQ) |

72.3 |

274.5 |

0 |

0 |

346.8 |

0 |

0 |

Environmental Accounting

Tosoh has introduced environmental accounting to quantitatively assess the investments, costs, and effectiveness of environmental protection measures. Environmental investments totaled 2.6 billion yen, primarily for equipment related to energy-conservation and fuel-reduction measures.

Environmental expenses increased approximately 2.3 billion yen from fiscal 2021, to 20.7 billion yen. Economic benefits amounted to 6.1 billion yen, including proceeds from the sale of valuable resources and cost reductions achieved through energy conservation.

Scope of aggregation: Nanyo Complex, Yokkaichi Complex, Tokyo Research Center

Environmental Accounting Costs

(Unit: Hundred million yen)

| Category |

Description of

key initiatives |

Investments |

Costs |

| FY2019 |

FY2020 |

FY2021 |

FY2022 |

FY2021 |

FY2022 |

| Costs within complexes |

|

94.4 |

80.8 |

73.3 |

23.3 |

150.3 |

162.6 |

| |

Pollution prevention costs |

Exhaust gas and

wastewater treatment measures |

49.1 |

14.2 |

48.9 |

9.8 |

88 |

95.4 |

Global environmental

protection costs |

Electricity and

fuel reduction measures |

38.1 |

64.3 |

11.2 |

12.2 |

25.2 |

27.9 |

| Resource recycling costs |

Raw material and

waste recovery measures |

7.2 |

2.3 |

13.2 |

1.3 |

37.1 |

39.3 |

| Management activity costs |

Environmental management,

environmental impact assessment, environmental reporting, environmental impact monitoring |

0.1 |

0.9 |

0.3 |

0.8 |

6.5 |

8.9 |

|

|

|

| R&D costs |

Development of

technologies to reduce environmental impact and development of environment-related products |

2.2 |

3.8 |

2.4 |

1.7 |

25.4 |

33.6 |

|

| Social activity costs |

Association dues,

tree planting, community coexistence |

0 |

0 |

0 |

0 |

0.3 |

0.3 |

| Other |

|

0 |

0 |

0 |

0 |

0.9 |

1.1 |

| Total |

|

96.8 |

85.5 |

76 |

25.8 |

183.4 |

206.5 |

Economic impact

(Unit: million yen)

| Details |

FY2019 |

FY2020 |

FY2021 |

FY2022 |

| Earnings |

Amount of contracted

reuse treatment of external industrial waste, sale of substandard products |

11.6 |

14.3 |

15.3 |

12.7 |

| Cost reduction |

Energy

conservation |

Reduction of energy costs

through energy conservation |

39.3 |

47.5 |

15.6 |

7 |

Resource

conservation |

Reduction of waste

disposal costs associated with resource conservation or recycling |

7.9 |

7.5 |

29.3 |

41.6 |

| Total |

|

58.8 |

69.3 |

60.2 |

61.3 |

The figures are based on the "Environmental Accounting Guidelines 2005" established by Japan’s Ministry of the Environment. However, the figures for areas not specified in the guidelines are based on assumptions made by Tosoh.

Environmental Protection Initiatives

Improving Education

Tosoh regularly holds lectures by invited experts and local governments, and the departments in charge of environmental management at its complexes provide on-site education and liaison opportunities for manufacturing departments to report case studies and disseminate regulations.

For Group companies, Tosoh holds briefings on trends in revisions of environmental laws and regulations and examples of violations through the Tosoh Group Safe Work Environment Network. We also promote compliance with laws and regulations through legal checklists and other means.

Educational

achievement items |

Details |

Number of events, etc. |

| Lectures by outside speakers |

Related to Waste Disposal and Public Cleaning Act (including Tosoh Group) |

Four |

| About the Yokkaichi environmental plan |

One |

| Training |

Refresher training for pollution control managers |

Two |

| Visiting environmental education, liaison meetings with manufacturing sites |

All manufacturing departments |

| EMS internal auditor training |

Two |

| Environmental management education |

Four |

| In-house briefings |

Briefing on legal revisions, environmental overview report |

Two |

| Regular environmental liaison meetings |

Two |

Biodiversity Preservation

| Key performance indicators (KPIs) |

FY22 Targets |

FY22 Results |

Appraisal |

| Promoting Biodiversity Preservation |

- Understand the relationship between business activities and biodiversity

- Establish biodiversity action guidelines

- Promote biodiversity preservation

|

Achieved |

Basic Concept

Tosoh Group's chemical products can have a significant impact on the ecosystem if they are not properly managed during the manufacturing process. The entire supply chain may also have ecological impacts because the manufacture of chemical products uses resources such as energy, mined natural resources, and water resources. The Tosoh Group is committed to the preservation of biodiversity through its business activities and contributions to local communities with the aim of realizing a sustainable society.

Furthermore, in the interest of further educating our employees, we have included initiatives for biodiversity preservation activities in the action guidelines of our Basic Principles Regarding the Environment, Safety, and Health since fiscal 2021, and are working to heighten awareness of nurturing biodiversity through in-house education and other means.

Biodiversity Preservation Initiatives

Endorsement of and Participation in Councils and Other Organizations

The Tosoh Group promotes community-based environmental protection activities that lead to biodiversity under the Action Guidelines of the Basic Principles Regarding the Environment, Safety, and Health, and each region conducts its own voluntary activities. As part of our efforts to address the marine plastic problem, we have signed the "Declaration for Solving the Plastic Marine Litter Problem" of the Japan Plastics Industry Federation. The purpose of this activity is to promote voluntary efforts that address the marine plastic problem and to appeal to society the urgency of the situation.

Addressing the Plastic Problem

Tosoh has positioned the promotion of material and chemical recycling as its contribution to society in reducing waste plastics. It is developing recycling technologies through joint research with universities and national research institutes, based on the progress of the circular economy. One example is our participation in the Developing Liquid-Phase Hybrid Recycling Technology for Multilayer Plastic Films, which was adopted by the New Energy and Industrial Technology Development Organization (NEDO) as a leading research project. We aim to develop recyclable plastics, and at the same time, we are actively pursuing initiatives to mitigate our environmental impact.

Coordination with Business Activities

The Nanyo Plant has concluded an agreement with Shunan City in Yamaguchi Prefecture for the effective use of branches pruned from roadside trees and other materials generated around the city as woody biomass fuel, thereby contributing to the effective use of limited resources and the prevention of global warming. Moreover, Tosoh composts the pruned branches, fallen leaves, and other materials generated on the premises and uses them for tree growth and green space management. Furthermore, in December 2021, Shunan City and a company in the vicinity jointly signed an agreement to collaborate on woody biomass material utilization and forest maintenance.

We will continue to investigate the feasibility of implementing joint projects for woody biomass materials and forest maintenance, utilizing city-owned forests.

Contribution to Local Communities

The Tosoh Group promotes community-based environmental protection activities to realize a society in harmony with nature.

Satoyama Preservation Activities

Tosoh’s Nanyo and Yokkaichi Complexes are actively involved in local Satoyama Preservation Activities. Every year, the Nanyo Plant participates in the Forestation for Water Conservation Promotion Project hosted by Yamaguchi Prefecture, and the Yokkaichi Complex carries out Satoyama Preservation Activities hosted by the Yokkaichi Nature Conservation Promotion Committee. We will continue to promote Satoyama preservation activities to maintain the ecosystem.

Satoyama preservation activities (Nanyo area)

Community Volunteer Cleanup

Tosoh conducts urban cleanups in the neighborhoods of its business sites, as well as around beaches and rivers. The Nanyo Complex strives to beautify the surrounding area through community contribution activities such as Clean Up My NANYO, as well as cleanup projects in neighborhoods and at Nagata Beach. The Yokkaichi Complex participates in the Kasumigaura Regional Environmental Promotion Association (KIEP’S), which consists of 31 companies and organizations, and continues to conduct environmental volunteer activities. An example is KIEP'S support for the Mie Prefecture-sponsored Ise Bay Forest, River, and Sea Cleanup Campaign to clean up nearby beaches. From fiscal 2023, the Tosoh Labor Union will also register with KIEP’S.

Nagata Coastal Cleanup (Nanyo area)

Takamatsu Coastal Cleanup (Yokkaichi area)

ISO Certification Status (as of May 2022)

Upper row: Certification number

Lower row: Expiration date

| Company Name |

Target Business Sites |

ISO9001 |

ISO14001 |

ISO13485 |

OHSAS18001/ |

| ISO45001 |

| Tosoh Corporation |

Nanyo Complex |

4562186

December 2023 |

4428758

November 2022 |

— |

— |

| Yokkaichi Complex |

4451472

December 2022 |

4022641

February 2024 |

— |

— |

| Bioscience Division |

— |

— |

SX6014232 0 0001

August 2022 |

— |

| Asia Industry Co., Ltd. |

|

RQ0332

June 2024 |

— |

— |

— |

| Organo Corporation |

Plant Business |

4446254

March 2023 |

— |

— |

— |

| Tsukuba Factory |

4514686

July 2023 |

4310776

July 2025 |

— |

— |

| Performance Products Business |

4157900

August 2024 |

— |

— |

— |

| Organo Plant Service Corporation |

4389327

June 2025 |

— |

— |

— |

| Sankyo Chemical Industry, Inc. |

|

— |

4161782

June 2024 |

— |

— |

| Sanwa General Contractor Inc. |

|

MSA-QS-4520

January 2025 |

MSA-ES-1663

January 2025 |

— |

MSA-SS-273

November 2022 |

| Seiwakouki Co., Ltd. |

|

MSA-QS-2486

March 2025 |

— |

— |

MSA-SS-430

March 2025 |

| Taihei Chemicals, Ltd. |

|

JMAQA-2591

May 2023 |

JMAQA-E904

May 2023 |

— |

— |

| Taiyo Vinyl Corporation |

|

4451472

December 2022 |

4022641

February 2024 |

— |

— |

| Tosoh AIA, Inc. |

|

01-100-028410

August 2022 |

— |

SX6014232 0 0001

August 2022 |

— |

| Tosoh SGM Corporation |

|

4336732

July 2022 |

4428758

November 2022 |

— |

— |

| Tosoh Quartz Corporation |

Yamagata Headquarters/Factory |

3900738

September 2023 |

4258833

May 2025 |

— |

4437282

November 2022 |

| Yonezawa Factory |

3900738

September 2023 |

4258833

May 2025 |

— |

4437282

November 2022 |

| Sakata Factory |

3900738

September 2023 |

4258833

May 2025 |

— |

4437282

November 2022 |

| Tokyo Headquarters |

3900738

September 2023 |

4258833

May 2025 |

— |

4437282

November 2022 |

| Tosoh Information Systems Corporation |

Nanyo Complex |

— |

4428758

November 2022 |

— |

— |

| Yokkaichi Complex |

— |

4022641

February 2024 |

— |

— |

| Tosoh Silica Corporation |

|

3973776

December 2023 |

4428758

November 2022 |

— |

— |

| Tosoh Speciality Materials Corporation |

|

JP022490

May 2025 |

JP022548

June 2025 |

— |

— |

| Tosoh Zeolum, Inc. |

|

JP022455

June 2025 |

— |

— |

— |

| Tosoh Ceramics Co., Ltd. |

|

— |

— |

MD607327

January 2023 |

— |

| Tosoh Sogo Service Co., Ltd. |

Nanyo Branch |

— |

4428758

November 2022 |

— |

— |

| Yokkaichi Branch |

— |

4022641

February 2024 |

— |

— |

| Tosoh Techno-System, Inc. |

|

01-100-028410

August 2022 |

— |

SX6014232 0 0001

August 2022 |

— |

| Tosoh High-Tec, Inc. |

|

01-100-028410

August 2022 |

— |

SX6014232 0 0001

August 2022 |

— |

| Tosoh Hyuga Corporation |

|

4027888

April 2024 |

4211329

November 2024 |

— |

— |

| Tosoh Finechem Corporation |

|

JSAQ 001

May 2023 |

4428758

November 2022 |

— |

— |

| Tosoh Logistics Corporation |

Nanyo Headquarters/Yamaguchi Koun Corporation/Koun Marine Co., Ltd. |

4448957

December 2022 |

— |

— |

— |

| Yokkaichi Branch/Yokkaichi Koun Corporation |

4448957

December 2022 |

— |

— |

— |

| Osaka Sales Division/Kansai Kaiun Co., Ltd. |

4448957

December 2022 |

— |

— |

— |

| Tokyo Branch/Funabashi Logistics Center/Ibaraki Sales Office/Satte Sales Office/Keiyo Koun Corporation |

4448957

December 2022 |

— |

— |

— |

| Tosoh Analysis and Research Center Co., Ltd. |

Nanyo Division |

JCQA-1070

March 2023 |

4428758

November 2022 |

— |

— |

| Yokkaichi Division |

JCQA-1070

March 2023 |

4022641

February 2024 |

— |

— |

| Tokyo Sales Division (includes Yamagata, Tsuchiura, Totsuka) |

JCQA-1070

March 2023 |

— |

— |

— |

| Toho Acetylene Co., Ltd. |

|

00QR・428

October 2024 |

05ER・496

January 2023 |

— |

— |

| Tohoku Denki Tekko Co., Ltd. |

|

3981908

December 2023 |

— |

— |

— |

| Tohoku Tosoh Chemical Co., Ltd. |

Sakata Factory |

4435323

January 2023 |

4435326

February 2023 |

— |

— |

| Tohoku Maintenance Industry Co., Ltd. |

|

— |

4553486

October 2023 |

— |

— |

| Nippon Miractran Co., Ltd. |

|

Q4559

August 2023 |

E2096

August 2023 |

— |

— |

| Hyuga Unyu Co., Ltd. |

|

MSA-QS-3387

March 2023 |

— |

— |

— |

| Plas-Tech Corporation |

Nabari Factory |

4445419

December 2022 |

— |

— |

— |

| Tsukuba Factory |

4445419

December 2022 |

— |

— |

— |

| Hokuetsu Kasei Co., Ltd. |

|

4295287-2A

February 2025 |

— |

— |

— |

| Rin Kagaku Kogyo Co., Ltd. |

|

4143382

August 2024 |

JP022552

July 2025 |

— |

— |

| Rensol Co., Ltd. |

|

4295287-2B

February 2025 |

— |

— |

— |

| Lonseal Corporation |

|

2158

January 2023 |

E1840

December 2022 |

— |

— |

| Mabuhay Vinyl Corporation |

|

TUV100 05 3003/1

September 2023 |

TUV104 05 2592

June 2022 |

— |

— |

| Philippine Resins Industries, Inc. |

|

CPI/4338IQ/10/9/725

October 2022 |

CPI/4338IE/10/9/725

October 2022 |

— |

— |

| Tosoh Advanced Materials Sdn. Bhd. |

|

01 100 1835567

February 2025 |

01 104 1835567

February 2025 |

— |

— |

| Tosoh Hellas Single Member S.A. |

|

GR002662

April 2025 |

GR000862

January 2023 |

— |

— |

| Tosoh Quartz Co., Ltd. |

|

TW001/00834

December 2024 |

TW06/01032

November 2023 |

— |

— |

| Tosoh Quartz, Inc. |

|

NQA-10527

April 2023 |

— |

— |

— |

| Tosoh Quartz Korea Co., Ltd. |

|

KQA-Q213096

June 2022 |

— |

— |

— |

| Tosoh Polyvin Corporation |

|

01 100 033496

August 2024 |

— |

— |

— |

| Tosoh SMD, Inc. |

|

21975

October 2024 |

21976

October 2024 |

— |

— |

| Tosoh SMD Korea, Ltd. |

|

— |

EMS-0089

November 2024 |

— |

— |

| Tosoh (Guangzhou) Chemical Industries, Inc. |

|

CN15/31335

October 2024 |

— |

— |

— |

Tosoh (Shanghai) Electronic Materials |

|

00621Q30470R3M

April 2024 |

00620E30130R2M

April 2023 |

— |

— |

| Tosoh (Shanghai) Polyurethane Co., Ltd. |

|

00321Q30494R1S

November 2024 |

00321E20325R1S

November 2024 |

— |

— |

| Tosoh (Ruian) Polyurethane Co., Ltd. |

|

00320Q30434R1M

December 2023 |

— |

— |

— |